Control Cabinets

Ideal connectors between control cabinet modules and units, providing flexible use of space in electrical installations

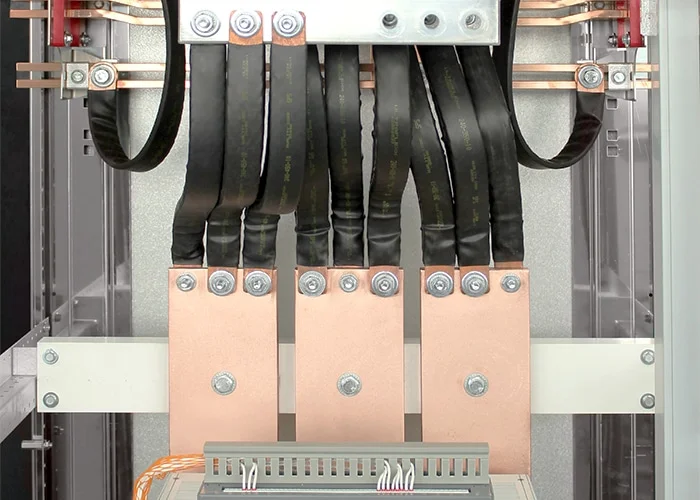

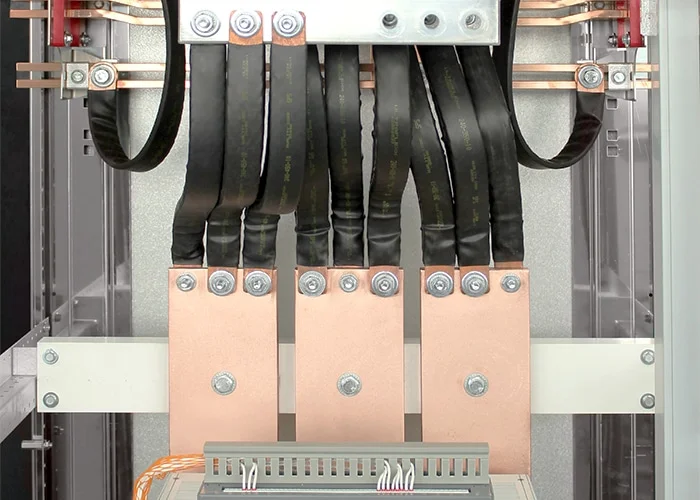

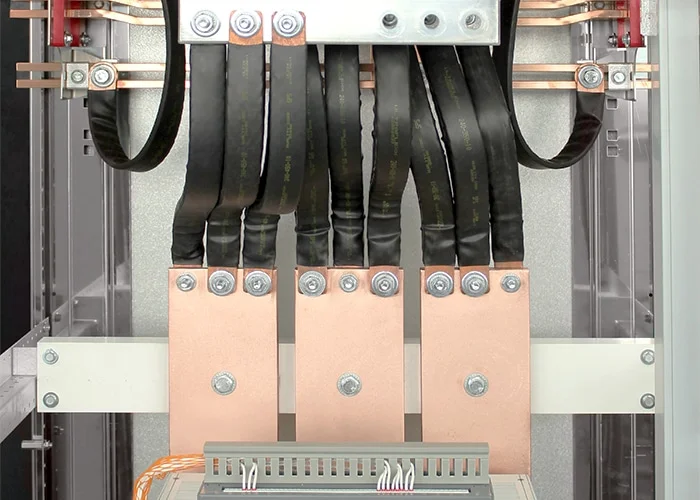

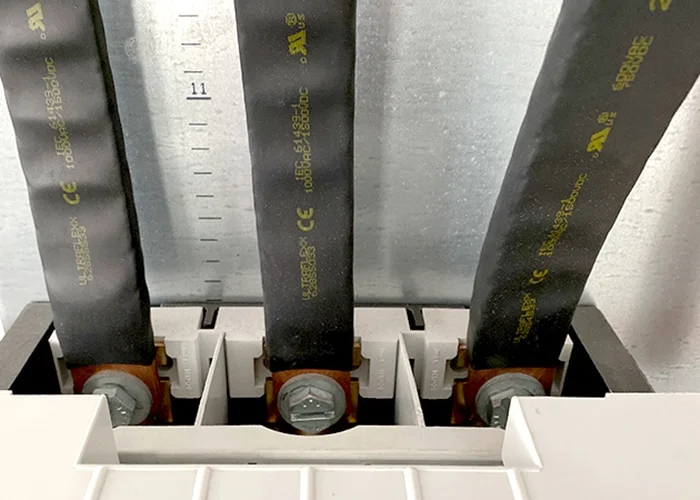

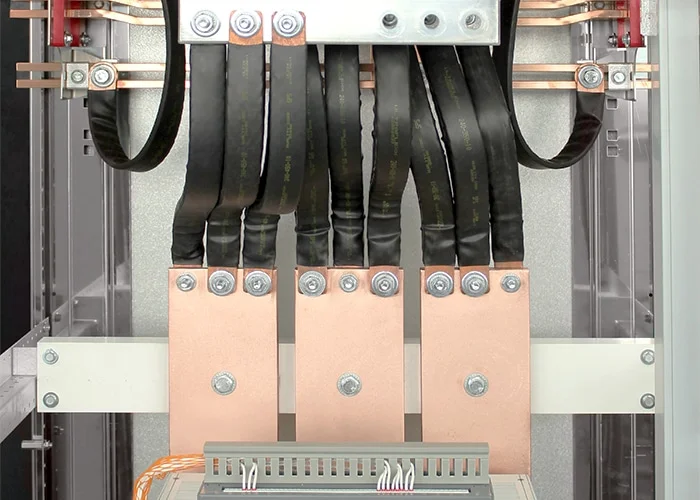

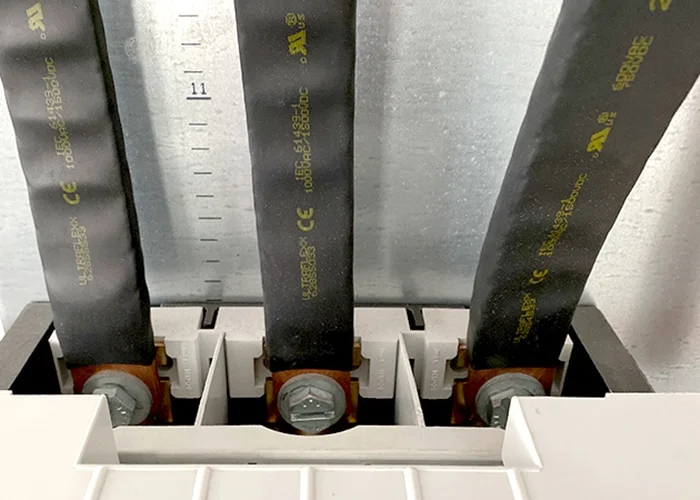

Ultraflexx® highly flexible busbars

Price Available on Request

UL 508

UL 508

RoHS

RoHS

Comprehensive technical details for Ultraflexx® highly flexible busbars to ensure optimal performance in your electrical installations.

Ultraflexx® busbars deliver unmatched performance with flat copper mesh technology and superior electrical conductivity for reliable power distribution.

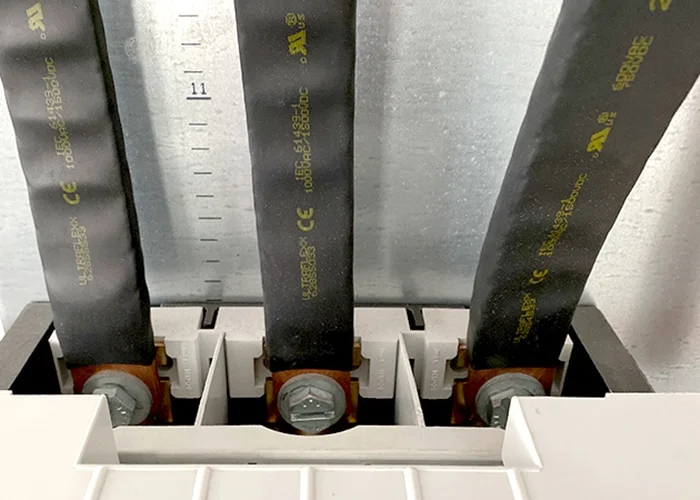

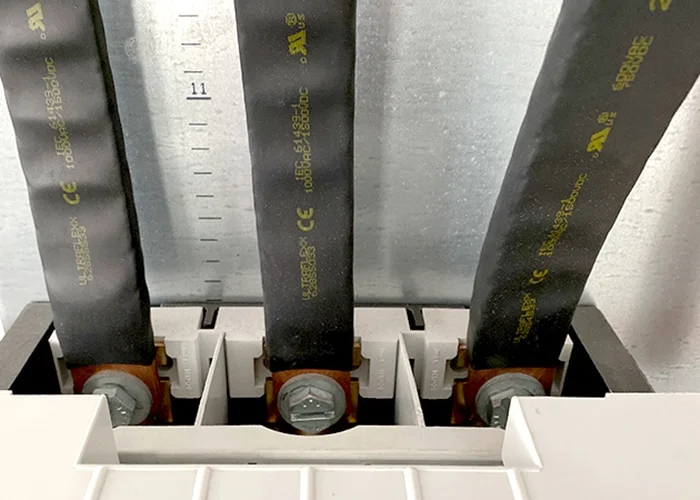

Excellent electrical conductivity of 58 MS/m with flat copper mesh construction ensures minimal power loss and optimal energy transfer in demanding industrial applications.

Specially designed for vibration-resistant connections with press-welded joints over the entire cross-section, providing superior mechanical stability and long-term reliability.

Operating temperature range from -55°C to +125°C with low heating during short circuits, ensuring consistent performance in extreme environmental conditions.

Supplied ready for use with highly flexible design that allows for easy installation and compensation of construction tolerances, reducing assembly time significantly.

Halogen-free polyolefin insulation with RoHS compliance and REACH certification ensures environmentally responsible electrical solutions without compromising performance.

Individual lengths and insulation options available on request with personalization capabilities and custom packaging specifications to meet specific project requirements.

Get the latest technical specifications and product updates

Ultraflexx® highly flexible busbars provide reliable electrical connections across diverse industrial applications, from control cabinets to vibration-sensitive installations.

Ideal connectors between control cabinet modules and units, providing flexible use of space in electrical installations

Flexible connectors that absorb vibrations and switching surges, perfect for demanding industrial environments

Best alternative to pre-assembled cables for applications requiring highly flexible electrical connections

Hear from professionals who rely on Ultraflexx® busbars for their most critical electrical installations and projects.

The Ultraflexx® busbars have revolutionized our control cabinet installations. Their vibration resistance and flexible design make them perfect for our industrial automation projects where traditional cables failed.

Maintenance Manager, ABC Manufacturing

The press-welded connections and superior electrical conductivity of Ultraflexx® busbars provide exactly what we need for our electrical panel designs. Installation time has been reduced significantly.

Design Engineer, TechSystems Inc

We've been using Ultraflexx® busbars for over three years in harsh industrial environments. The minimal contact resistance and operational reliability have exceeded our expectations consistently.

Operations Director, Industrial Solutions LLC

The wide operating temperature range and flame retardant properties make Ultraflexx® busbars ideal for our food processing facility. They handle temperature fluctuations without any degradation in performance.

Electrical Engineer, Midwest Food Processing

The ability to get custom lengths and individual insulation specifications has saved us considerable time and cost. ValuAdd's support in sourcing these specialized busbars has been exceptional.

Project Manager, Advanced Panel Solutions

In our automotive manufacturing line, Ultraflexx® busbars handle the constant vibrations and switching surges perfectly. The copper mesh design and press-welded connections provide the reliability we demand.

Electrical Supervisor, AutoTech Manufacturing

Explore our comprehensive range of copper busbar solutions designed to meet diverse electrical distribution requirements across industrial applications.

Solid copper bars designed for primary or secondary distribution busbars, providing robust and reliable electrical connections for high-current applications.

Easy setup compact design with highly flexible and time-saving installation. No terminal lugs or tightening required, increased safety without crimped connections for better short-circuit behavior.

Very flexible laminated busbars made of Cu-ETP with high-quality insulation. Loose lamellae allow easy bending and twisting with excellent flexibility, material space saving, and UL approval.

Our technical experts can help you select the right busbar configuration for your specific application requirements.

Ready to discuss your electrical connection requirements? Our technical team is here to help you select the optimal Ultraflexx® busbar configuration for your project.

For immediate technical support, call +1 (555) 123-4567 or email [email protected]

For immediate technical support, call +1 (555) 123-4567 or email [email protected]