One unexpected electrical fault can bring an entire production line to a halt, a breaker trip, a VFD that refuses to restart, or a burning smell from a control panel. More often than not, the hidden culprit is a ground fault.

A ground fault occurs when electrical current escapes its intended path and flows to ground through equipment frames or unintended conductive surfaces. Something as simple as moisture, insulation breakdown, or damaged wiring can trigger it, and the consequences are costly.

The risk is real and widespread. According to the Electrical Safety Foundation International (ESFI) notes that an average of about 150 workplace electrical fatalities occurs each year, based on U.S. Bureau of Labor Statistics data for 2011–2023, alongside significant downtime, arc flash hazards, and equipment failures.

For plant engineers, controls engineers, maintenance teams, panel shops, and distributors, understanding and preventing ground faults is essential, not just for safety, but for uptime, productivity, and long-term electrical system reliability.

Key Highlights

Ground faults often cause unexpected trips, shutdowns, and equipment damage, usually due to moisture, insulation failure, or worn wiring.

Even minor leakage to ground can lead to fires, arc flash risks, and major control-system failures if not detected early.

Humidity, dust, washdown, and debris are the biggest contributors, creating accidental paths to ground in panels and machines.

Regular insulation tests, thermal scans, and inspections are the simplest ways to spot ground faults before they escalate.

ValueAdd provides reliable grounding, protection, and enclosure solutions that help reduce ground-fault risks and improve uptime.

What Is a Ground Fault?

A ground fault occurs when electrical current unintentionally leaves its normal path and flows from an energized conductor to ground or to a conductive surface that was never meant to carry current, such as a metal enclosure, machine frame, or conduit system. Instead of completing its intended circuit, the current “leaks” to ground, creating a dangerous and abnormal condition.

Ground faults typically happen when insulation fails, wiring is damaged, or moisture or contamination creates a conductive path. Even small faults can cause rapid heating, arcing, or equipment shutdowns, making them a major reliability and safety concern in industrial environments.

How Ground Faults Differ from Other Electrical Faults

Not all electrical faults behave the same, and misdiagnosing them can lead to wasted troubleshooting time, repeated failures, and unnecessary equipment replacement.

Electrical Fault Type | Description | Key Risk |

Ground Fault | Current unintentionally flows to ground or grounded surfaces | Shock, fire, equipment shutdown |

Short Circuit | Current flows directly between conductors of different potentials (e.g., phase-to-phase) | Very high current surge and breaker trip |

Arc Fault | Current jumps through the air between conductors or to ground, forming an arc | Intense heat, fire, arc flash risk |

Leakage Current | Small, unintended current flow to ground below trip thresholds |

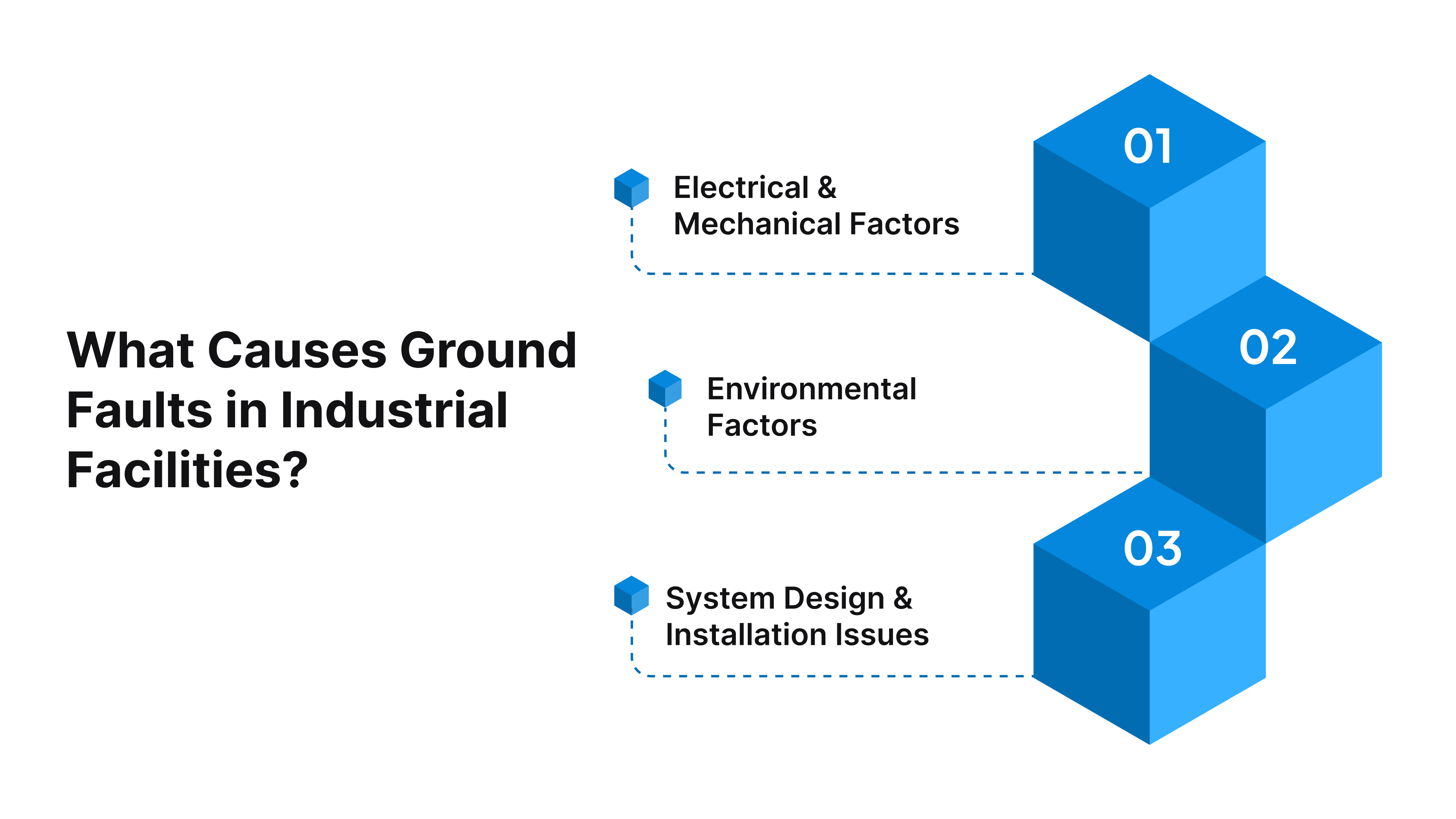

What Causes Ground Faults in Industrial Facilities

Ground faults rarely occur without warning; most develop gradually as equipment, wiring, and environmental conditions deteriorate. Understanding the root causes helps engineers and maintenance teams stop failures before they escalate into costly downtime or safety hazards.

Electrical & Mechanical Factors

Electrical systems inside plants experience continuous stress from heat, vibration, movement, and load changes. Over time, these conditions weaken insulation and connections, making unintentional current paths more likely.

Insulation breakdown caused by aging, temperature cycling, vibration, mechanical flexing, or overload conditions.

Cable or conductor damage, including abrasion from conduit edges, bending stress in drag chains or cable trays, rodent damage, or machine motion.

Loose or corroded terminals that create high-resistance heating or intermittent fault paths.

Environmental Factors

Harsh or uncontrolled environments are one of the most common sources of ground fault conditions, especially where moisture or contamination compromises electrical insulation.

Moisture ingress, humidity, condensation, or washdown entering control panels or junction boxes.

Dust, oil, metal shavings, and conductive debris are creating unintended bridge paths across components and terminals.

Outdoor installations exposed to UV, temperature swings, salt, or chemicals accelerate insulation failure.

System Design & Installation Issues

Even well-built systems can fail early when design decisions don’t match field conditions or installation practices overlook grounding and thermal principles.

Improper grounding and bonding that leave equipment unprotected when faults occur.

Overloaded circuits or undersized conductors accelerate insulation breakdown.

Incorrect enclosure selection for the application, using non-sealed enclosures in wet or corrosive environments, or insufficient NEMA/IP protection.

Poor thermal management, leading to overheating and premature failure of insulation, drives, and control components.

Where Ground Fault Issues Commonly Occur in Industrial Operations

Ground faults arise in many everyday applications across manufacturing, utilities, OEM equipment, and automation systems. These real-world use cases highlight where problems originate and why proactive prevention matters.

VFD-Driven Motor Systems: Ground faults triggered by leakage or insulation breakdown cause frequent drive trips, unstable speed control, or complete line shutdowns in conveyors, mixers, pumps, and packaging machines.

Washdown or Hygienic Production Environments: Moisture intrusion into control panels or junction boxes during cleaning cycles forms conductive paths, leading to breaker trips, corrosion, and accelerated equipment failure in food & beverage, dairy, and pharmaceutical plants.

Outdoor or Harsh-Environment Control Enclosures: UV exposure, temperature swings, and humidity cause cracking insulation, condensation buildup, and ground-fault events affecting pumps, compressors, chemical handling systems, HVAC, or utility power systems.

Robotics and Motion-Intensive Machinery: Cable wear in moving cable chains, robotic arms, or automated material handling leads to insulation abrasion and intermittent faults difficult to diagnose.

Water & Wastewater Pumping Applications: High-moisture environments and long cable runs create leakage paths, damaging pumps, soft starters, and motor-control components.

CNC, machining, or metal fabrication: Conductive dust accumulates inside enclosures and drive cabinets, eventually causing tracking faults or ignition risk.

Panel shops and OEM skid builders: Improper grounding, undersized components, or panel layout limitations can produce long-term reliability issues once equipment is deployed in harsher-than-expected field conditions.

Legacy infrastructure and modernization projects: Aging wiring insulation, loose terminations, and degraded grounding systems significantly increase the risk of faults during system upgrades or expansions.

UPS-protected control circuits: Ground faults on low-voltage control wiring can cause unexpected control-power drops, disabling safety interlocks or emergency shutdown systems.

Distributed I/O and sensor networks: Minor leakage currents create erratic sensor signals, false triggers, and communication instability that can halt automated processes.

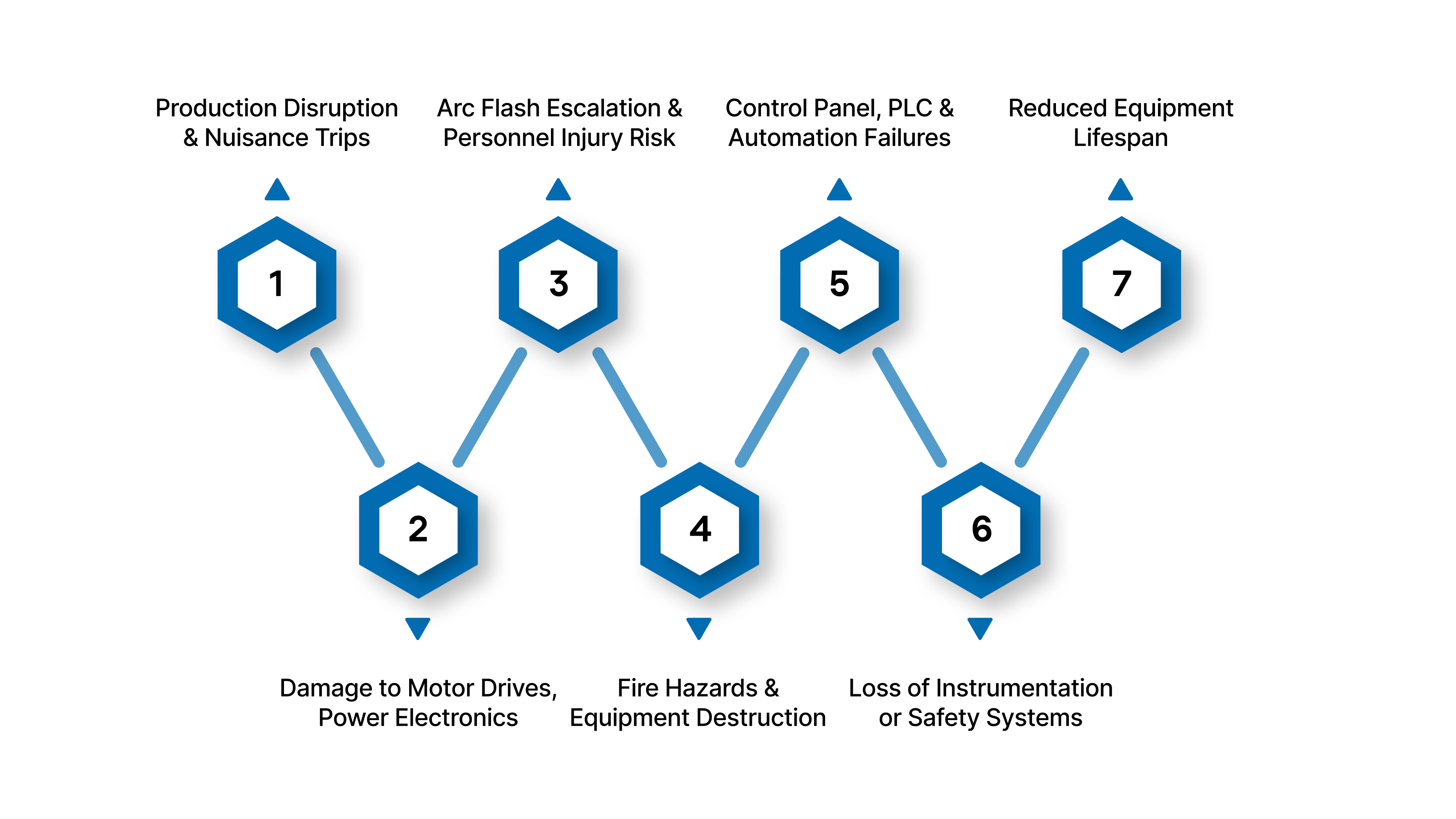

Industrial Consequences of Ground Faults

Ground faults have consequences far beyond a tripped breaker, they can jeopardize production, safety, and asset reliability across an entire facility. What starts as a small leakage path can quickly escalate into full system shutdowns, equipment failures, or life-threatening hazards.

A. Production Disruption & Nuisance Trips

Even minor ground faults often trigger protective devices, causing unexpected shutdowns, stalled equipment, and lost production time. These events may appear as nuisance alarms but often signal underlying insulation failure or contamination.

Common impact: delayed orders, overtime labor, scrap material, and reduced throughput.

In high-speed manufacturing, even 5–10 minutes of downtime can equal thousands of dollars in lost output.

B. Damage to Motor Drives, Soft Starters & Power Electronics

Variable-frequency drives (VFDs), soft starters, and other power electronics are highly sensitive to leakage currents and ground-fault paths.

Ground faults can trigger drive faults, corrupt IGBT switching, or destroy output stages.

Repeated nuisance trips often precede catastrophic failure.

Cost implication: VFD replacement can run from $3,000 to $35,000+, depending on horsepower, not including downtime.

C. Arc Flash Escalation & Personnel Injury Risk

A ground fault can escalate into an arc flash event if the current path ionizes air or jumps across components.

Arc flashes generate temperatures hotter than the surface of the sun (~35,000°F), causing severe burns, equipment destruction, and explosion forces.

Safety impact: severe injuries, regulatory exposure, OSHA violations, and expensive litigation.

D. Fire Hazards & Equipment Destruction

Sustained ground-fault currents generate extreme heat inside cables and components.

Can ignite insulation, panel wiring, or combustible contamination.

Fires often occur inside enclosures where early warning is limited.

E. Control Panel, PLC & Automation Failures

Ground faults inside control panels can cause PLC resets, I/O loss, sensor failure, or full automation collapse.

Typical symptoms: sporadic faults, unexplained process behavior, communication errors.

This makes troubleshooting difficult and increases downtime duration.

F. Loss of Instrumentation or Safety Systems

When critical sensing or safety circuits fault to ground, facilities may temporarily lose:

Level, temperature, or pressure feedback

Safety-interlock or e-stop functionality

Communication between distributed systems

This can put operations and personnel at significant risk, especially in water/wastewater, chemical processing, food & beverage, and high-energy manufacturing environments.

G. Reduced Equipment Lifespan & Higher Maintenance Costs

Even low-level leakage current that does not trip breakers accelerates insulation aging and erodes conductor integrity.

Equipment reaches end-of-life years earlier.

Maintenance becomes reactive instead of planned.

Total cost of ownership increases significantly.

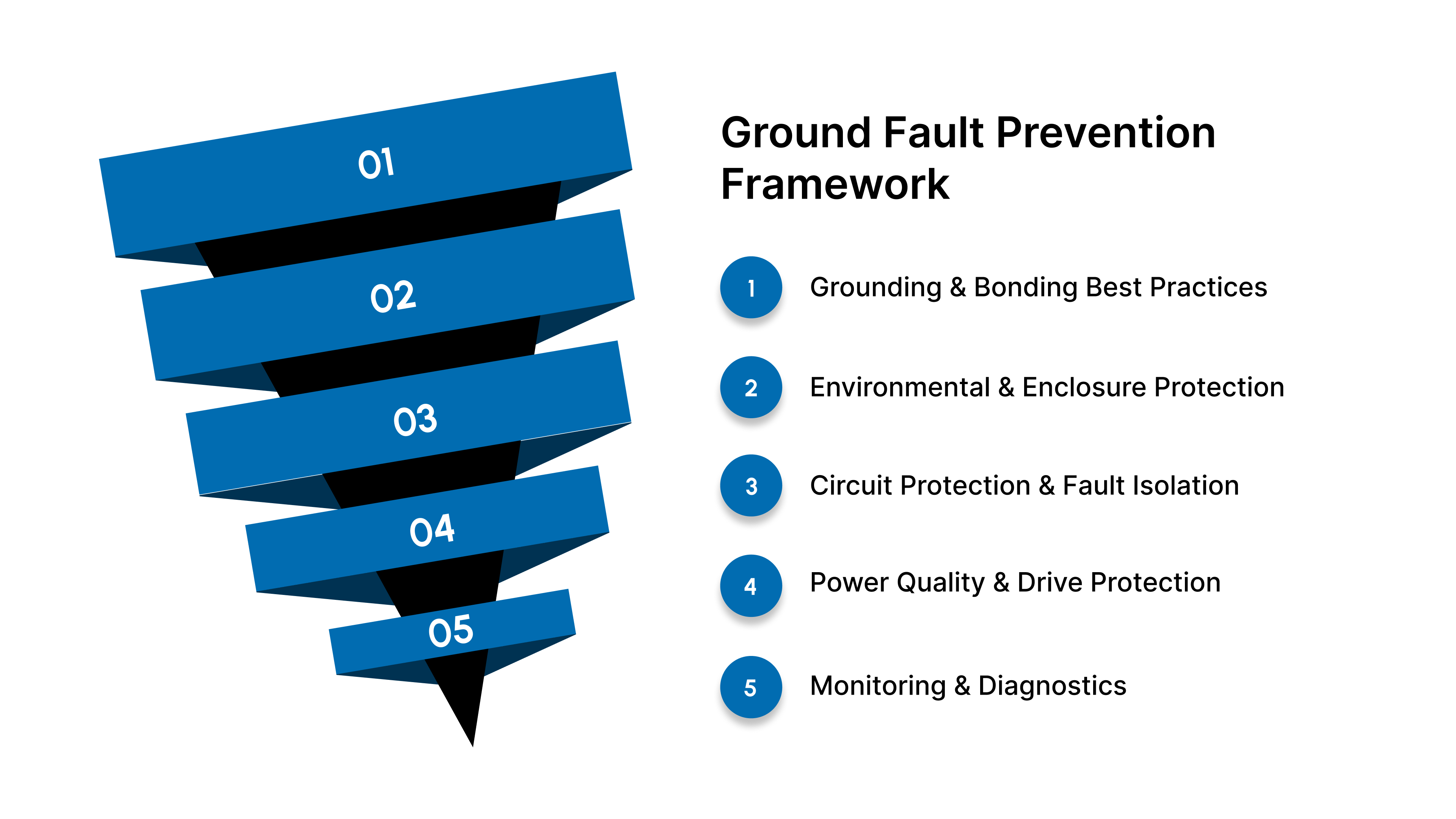

5. Ground Fault Prevention Framework

Preventing ground faults is far more effective and affordable than dealing with failures after they occur. A robust prevention strategy combines proper grounding, environmental protection, circuit protection technology, and proactive monitoring to eliminate both catastrophic events and subtle early-stage failures.

A. Grounding & Bonding Best Practices

Proper grounding and bonding are the foundation of electrical safety and fault control. Without a low-impedance path to ground, protective devices cannot operate quickly enough to clear a fault safely.

Use properly sized grounding conductors and dedicated ground paths to ensure fast and predictable fault clearing.

Bond all metal enclosures, raceways, and panel components to maintain an equipotential surface that prevents hazardous touch voltages.

Follow established standards including NEC, UL 508A, and IEEE grounding guidelines for control panel and industrial power system design.

Proper grounding reduces the energy available to faults, preventing escalation into arc flash, drive damage, or persistent hidden failures.

B. Environmental & Enclosure Protection

Most ground faults originate from moisture or contamination entering equipment spaces, often due to enclosure selection or sealing issues.

Select the right enclosure rating (NEMA or IP) based on real-world environment, not assumed or historical conditions (e.g., washdown, NEMA 4X/IP66; dusty machining, NEMA 12).

Implement climate control, such as air conditioners, heat exchangers, or panel heaters, to reduce condensation, heat stress, and humidity cycling.

Use proper cable entry protection (glands, drip loops, sealing grommets) to prevent water ingress and particulate contamination.

Managing the environment inside the enclosure extends component life and prevents moisture paths that create ground faults and nuisance shutdowns.

C. Circuit Protection & Fault Isolation

When a fault does occur, controlling its energy and isolating it quickly is essential to protect equipment and workers.

Use ground-fault breakers and disconnect switches to isolate specific loads or zones without shutting down an entire facility.

Apply overcurrent protection correctly so long-duration fault energy does not degrade insulation or ignite combustible material.

Load-break switches provide a safe local shutdown during maintenance without needing to de-energize entire systems.

Selective coordination reduces downtime by ensuring only the affected section of the system is taken offline.

D. Power Quality & Drive Protection

Power electronics such as VFDs are especially susceptible to leakage and grounding issues.

Install harmonic filters, line reactors, and power conditioning devices to stabilize current and reduce electrical stress on insulation.

Use drive output filters to prevent reflected-wave voltage spikes that damage motor windings and insulation.

Healthy power quality extends drive and motor life and reduces nuisance trips attributed to ground faults.

E. Monitoring & Diagnostics

Most serious ground faults begin as small, low-level leakage events that go unnoticed, unless monitored.

Install ground-fault and insulation-monitoring relays for early warning before shutdown occurs.

Integrate alarms into PLC/SCADA systems for real-time visibility and fault trending.

Implement predictive maintenance routines, including insulation resistance testing and thermal imaging.

Detecting degradation early allows repairs during planned downtime instead of after failure.

9. Inspection & Maintenance Checklist

Regular inspection and preventive maintenance dramatically reduce the likelihood of developing ground faults. Use this checklist to identify early risks and strengthen system reliability before failures occur.

Inspection Task | What It Prevents |

Inspect control panels for moisture, condensation, or corrosion | Prevents tracking paths, leakage current, and insulation deterioration |

Check enclosure door seals, cable entry points, and unused knockouts | Maintains environmental integrity and blocks contaminants |

Perform torque checks on terminals and grounding connections | Eliminates loose joints that cause heat, arcing, and intermittent faults |

Visually inspect insulation for discoloration, brittleness, or cracking | Identifies early insulation failure before faults occur |

Clean dust, oil mist, metal shavings, and conductive residue | Prevents unintended conductive bridges and overheating |

Review nuisance trip logs or repeated fault alarms | Reveals recurring issues and hidden electrical degradation |

Conduct insulation resistance (megger) testing and trend results | Tracks insulation health and predicts failure risk |

Run thermal imaging scans to locate hotspots | Detects hidden heating, loose terminations, and overload conditions |

Inspect VFD cable routing and grounding integrity | Prevents leakage faults, noise problems, and unstable drive performance |

Test UPS systems, protective relays, and disconnects | Ensures reliable control-power continuity and fault clearing |

Verify proper enclosure ventilation or climate control | Reduces condensation, heat stress, and component aging |

Confirm grounding and bonding continuity throughout the system | Ensures fast fault clearing and safety compliance |

Schedule routine audits of equipment, load conditions, and protection coordination | Optimizes reliability and avoids unexpected shutdowns |

Small inspection efforts prevent large failures. A structured maintenance routine protects uptime, extends equipment life, and catches electrical problems long before they trigger ground faults or unplanned shutdowns.

How ValuAdd Supports Ground Fault Prevention & Electrical Reliability

ValuAdd supports OEMs, industrial facilities, panel shops, system integrators, and electrical distributors across North Carolina, South Carolina, and Virginia with complementary industrial electrical product lines and local technical expertise.

By representing manufacturers whose products work together across the control panel and power distribution ecosystem, Valuadd helps customers improve electrical reliability, prevent failure conditions, and optimize system performance.

The product solutions represented by Valuadd support key reliability and safety goals relevant to ground-fault prevention, including:

Industrial enclosures and environmental protection to reduce moisture and contamination-based insulation failure.

Motor control solutions such as soft starters, overload relays, contactors, and VFD-related components that minimize drive trips and downtime.

Circuit protection and switching, including disconnect switches, miniature and molded-case breakers, and load-break technologies to safely isolate faults.

Power quality and distribution solutions, such as line reactors and harmonic filters, help stabilize drive systems.

Control panel reliability components, including relays, monitoring relays, timers, pilot devices, and terminal blocks.

UPS solutions to maintain critical control power continuity.

Automation hardware such as PLCs, HMIs, and industrial PCs for resilient control architectures.

ValuAdd helps engineering and maintenance teams choose the right components for control panels, automation, motor control, and power distribution. They also work with electrical distributors on training, stocking, and customer support to ensure fast field response.

Conclusion

Ground faults often start as minor electrical issues but can quickly lead to safety risks, equipment damage, and costly downtime. Understanding their causes, spotting early signs, and taking preventive action helps protect critical processes and improve overall system reliability.

Reliable system design, proper component selection, and environmental protection are key to preventing failures before they happen. Partnering with knowledgeable technical resources helps engineering, maintenance, OEM, and panel-building teams make informed decisions that reduce risk and maximize uptime.

If your facility is experiencing unexplained shutdowns, recurring drive faults, or concerns about electrical reliability, the experts at ValuAdd are ready to help. Our team provides application guidance, product selection support, and collaboration with OEMs, panel shops, and distributors across NC, SC, and VA.

FAQ

1. How can industrial plants prevent ground faults proactively?

Use proper grounding and bonding, select the right NEMA/IP enclosures, maintain clean and dry environments, apply power-quality solutions, and implement monitoring relays and routine inspections.

2. What are the most common signs that a ground fault is developing?

Frequent trips, unstable VFD behavior, PLC resets, unusual panel heat, visible corrosion, insulation damage, or recurring alarms without a clear root cause.

3. What’s the difference between a ground fault and a short circuit?

A ground fault is current to ground, while a short circuit is conductor-to-conductor contact. Ground faults often start small and intermittent, whereas short circuits typically cause immediate interruption.

4. Why are ground faults especially dangerous in industrial facilities?

They can lead to equipment shutdowns, arc flash hazards, fire risk, control-system failures, and costly unplanned downtime.

5. How can environmental conditions contribute to ground faults?

Moisture, dust, condensation, oil mist, and conductive debris can create unintended conductive paths inside enclosures or around wiring, degrading insulation.