Many facilities struggle with crowded panels, inconsistent cable runs, and electrical layouts that slow maintenance teams during unplanned downtime. Procurement and operations leaders often face another challenge as well: selecting power distribution components that balance reliability, space efficiency, and long-term support without adding unnecessary complexity to the BOM. Busbars solve many of these day-to-day issues by creating cleaner, safer, and more predictable paths for power distribution.

Key Takeaways

Busbars create structured, high-capacity power paths that replace bulky cable bundles in MCCs, drive panels, switchgear, and distribution trunks.

Copper, aluminum, flat, tubular, laminated, and trunking systems each address different current demands, enclosure layouts, vibration levels, and installation distances.

Industrial plants, OEM machinery, commercial buildings, data centers, utilities, and retrofit projects use busbars to reduce heat issues, cut wiring time, and support stable uptime.

Effective busbar selection comes down to matching load levels, temperature limits, space constraints, environmental conditions, routing needs, maintenance access, and future expansion.

What Are Electrical Busbars?

Electrical busbars are solid conductors that move power within panels, switchgear, and distribution systems in a cleaner and more controlled way than bundles of cables. Their rigid, compact form creates predictable current paths that help reduce heat, connection failures, and maintenance-related interruptions. Most industrial setups rely on them because they support higher currents, simplify branching, and keep layouts consistent across panels and equipment lines.

With the basics covered, it becomes easier to compare the different busbar formats and see how each one fits a specific electrical layout or load requirement.

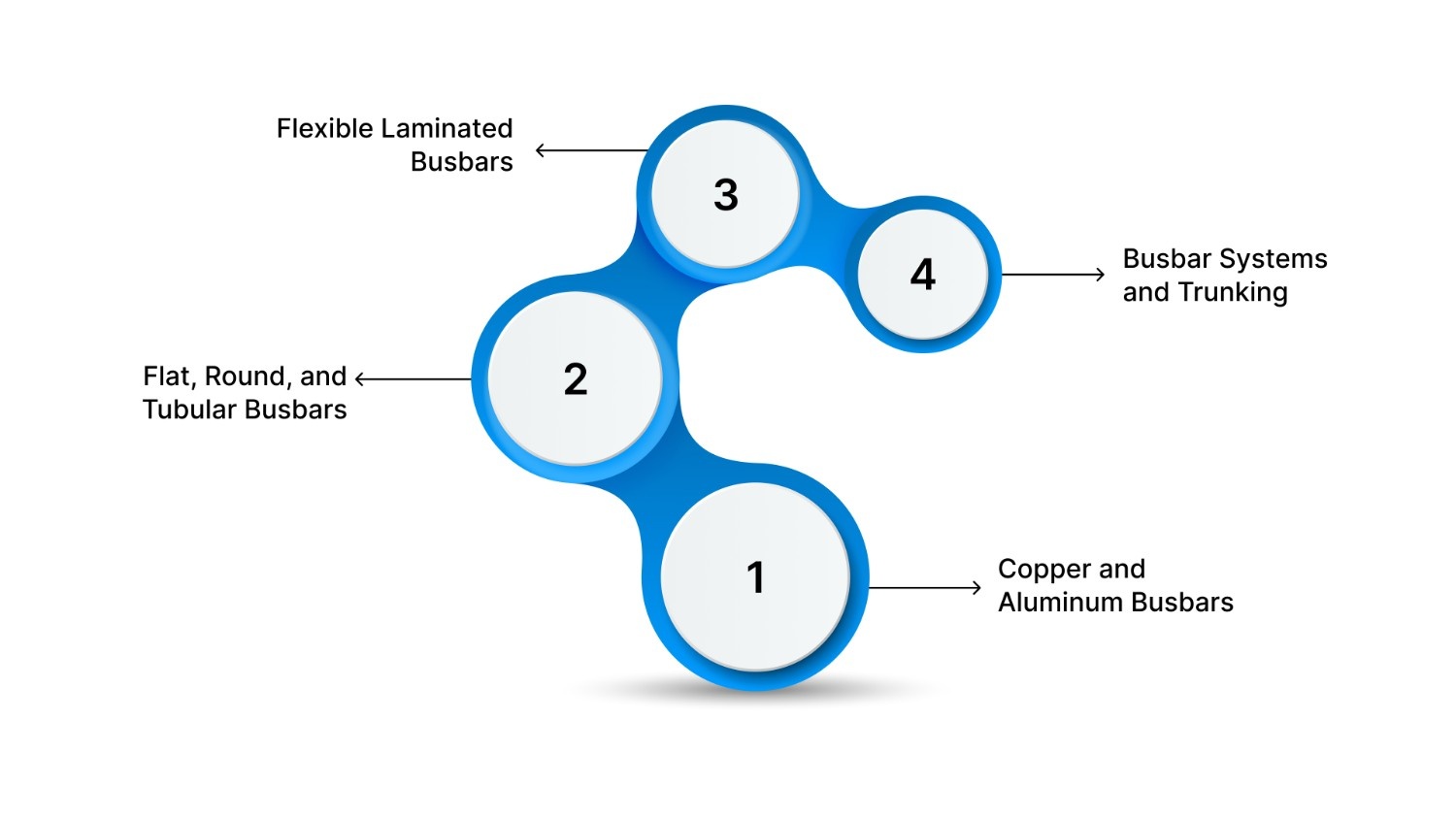

Types of Electrical Bus Bars

Types of electrical busbars vary by material, shape, and system design, each serving different power distribution needs. A clearer view of these groups helps narrow suitable options for your facility.

Copper and Aluminum Busbars

Copper busbars offer high conductivity and strong mechanical durability for demanding industrial loads. Aluminum busbars provide lighter weight and lower cost while maintaining adequate performance for many applications. Each material requires evaluating thermal behavior, availability, and long-term maintenance expectations.

Key Features

High electrical conductivity for stable current flow

Predictable thermal performance under continuous load

Material-specific weight and cost advantages

Suitable for both OEM builds and plant retrofits

Flat, Round, and Tubular Busbars

Flat busbars support efficient heat dissipation and simplify mounting in compact control panels. Round and tubular designs handle higher mechanical stresses where vibration or structural support matters. Selection often depends on available space, enclosure layout, and expected thermal conditions.

Key Features

Flat profiles for compact panel layouts and improved cooling

Round and tubular forms for mechanical strength and vibration resistance

Shape flexibility for load, spacing, and enclosure constraints

Flexible Laminated Busbars

Flexible laminated busbars accommodate tight bends and reduce connection points in crowded assemblies. Their layered construction helps lower inductance and supports stable performance in drive or inverter systems. These designs work well when panel geometry limits rigid conductor placement.

Key Features

Multi-layer construction for lower inductance and controlled electrical paths

Bend-friendly format for dense or irregular panel designs

Fewer joints that help reduce heat buildup and maintenance issues

Busbar Systems and Trunking

Busbar systems and trunking routes power across longer distances in large plants or commercial sites. Their modular tap-off points simplify expansion and support future load growth planning. Installation requirements, environmental exposure, and maintenance access shape the system choice.

Key Features

Modular structure allowing fast expansion across facility layouts

Long-distance distribution capability with consistent power handling

Standardized tap-offs supporting flexible equipment placement

Once the types are clear, the next step is seeing where these formats show up in real facilities and how different environments shape their use.

Where Are Electrical Busbars Used?

Where electrical busbars are used depends on load density, equipment layouts, and the reliability targets of each environment. A clearer view of these settings helps you pinpoint where busbars deliver the most practical value.

Common Settings Where Electrical Busbars Fit:

Setting | Typical Busbar Role | Operational Outcome |

|---|---|---|

Industrial Plants | Carry high-current feeds inside MCCs, drive cabinets, and distribution sections. | Cleaner layouts that support faster maintenance and stable equipment uptime. |

OEM Machinery | Serve as the main power backbone inside standardized machine panels. | Consistent panel builds that reduce wiring time and simplify repeat production. |

Control Panel Shops | Provide structured conductor paths for large loads and multi-device branches. | Easier panel assembly with fewer routing issues and predictable spacing. |

Commercial Facilities | Move power through main boards and multi-floor distribution routes. | Compact distribution paths that free space and support planned expansions. |

Data Centers | Feed UPS units, PDU banks, and high-density rack zones. | Stable delivery under fluctuating load conditions with simpler scaling options. |

Municipal and Utility Sites | Connect switchgear, transformer sections, and protection equipment. | Safer access during service work and reduced complexity in long-term upkeep. |

Retrofit Projects | Replace cable bundles in aging panels or older trunking systems. | Shorter outage windows during upgrades and more reliable future inspections. |

These settings highlight why busbars matter, so the next section focuses on the practical benefits that support day-to-day reliability and easier upkeep.

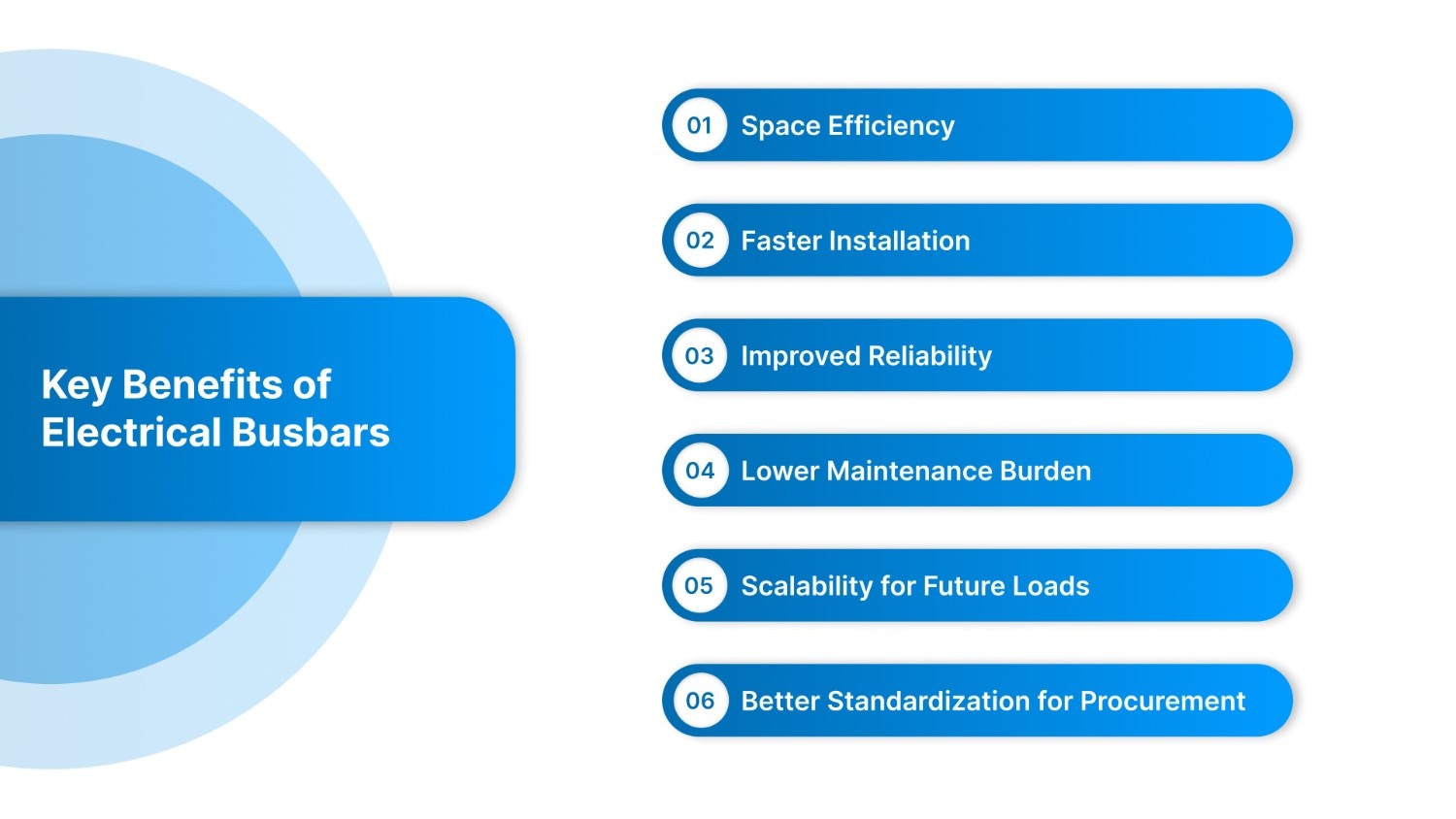

Key Benefits of Electrical Busbars

The benefits of electrical busbars extend beyond neat layouts and create practical gains for facilities aiming to improve reliability and reduce ongoing maintenance strain. A focused look at these advantages helps highlight where busbars support better operational decisions.

Key Benefits of Electrical Busbars include:

Space Efficiency

Compact profiles reduce congestion inside panels and distribution sections.

Cleaner routing supports easier access during inspections or quick repairs.

Faster Installation

Fewer connection points shorten wiring time during new builds or retrofits.

Structured paths reduce guesswork and limit layout changes during assembly.

Improved Reliability

Solid conductors have lower resistance compared to multiple parallel cables.

Reduced heat generation helps stabilize performance under continuous loads.

Lower Maintenance Burden

Fewer terminations minimize loose connections that often trigger unplanned downtime.

Predictable layouts allow quicker fault isolation for maintenance teams.

Scalability for Future Loads

Modular systems support tap-offs and extensions without major rewiring.

Consistent geometry helps accommodate new equipment or production lines.

Better Standardization for Procurement

One conductor format replaces multiple cable types across projects.

Streamlined BOMs improve stocking decisions and reduce purchasing delays.

Understanding what they offer leads naturally to the question of how to pick the right one, so the next section walks through the key factors to weigh during selection.

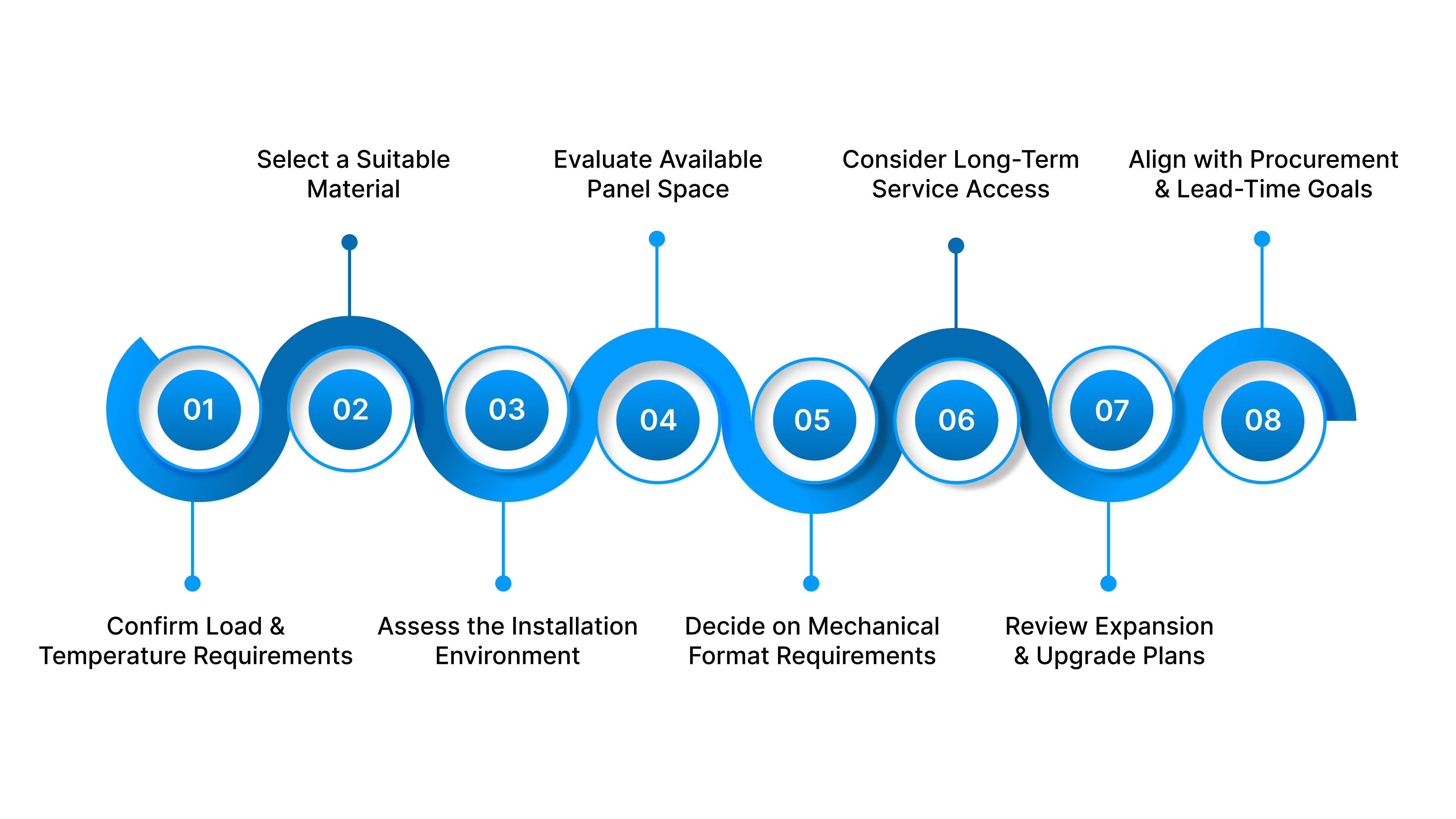

Key Factors When Selecting Busbars

Key factors when selecting busbars depend on performance, environment, and long-term service expectations. A shortlisting workflow gives a clear path from initial requirements to a narrowed set of busbar options without slowing procurement or engineering review.

Step 1: Confirm Load and Temperature Requirements: Identify expected current levels and duty cycles, then confirm allowable temperature rise inside the panel or enclosure.

Step 2: Select a Suitable Material: Compare copper and aluminum based on conductivity needs, cost constraints, mechanical strength, and availability through your preferred suppliers.

Step 3: Assess the Installation Environment: Review exposure to vibration, moisture, outdoor conditions, or contaminants to determine whether coatings, insulation, or reinforced formats are necessary.

Step 4: Evaluate Available Panel Space: Map breaker positions, cable entries, and equipment spacing to see if flat, laminated, or rigid bars align better with the layout.

Step 5: Decide on Mechanical Format Requirements: Check whether the design calls for a rigid structure or a bend-friendly format, especially in dense or irregular cabinet geometries.

Step 6: Consider Long-Term Service Access: Estimate maintenance frequency and inspection clearances to choose a routing style that minimizes disruptions and shortens troubleshooting time.

Step 7: Review Expansion and Upgrade Plans: Account for future load growth and determine if modular or trunking systems are needed for scalable tap-offs or new equipment lines.

Step 8: Align with Procurement and Lead-Time Goals: Match the short-listed formats with stocking patterns, fabrication timelines, and supplier reliability to avoid delays during build cycles.

Support from a technical partner can simplify these choices, and ValueAdd provides the application-level expertise needed to align each busbar selection with real operating conditions. Those considerations set the stage for a simple method to compare options, so the next part introduces a scoring worksheet that makes shortlisting more straightforward.

Guide to Choosing the Right Busbar

A scoring worksheet helps compare options side by side and highlights which format aligns best with electrical, mechanical, and procurement needs.

Busbar Scoring Worksheet

Instructions:

Score each category from 1 to 5

1 = Poor fit

5 = Excellent fit

Then, total the score for each busbar option.

Selection Category | Score Range | Notes for Evaluation |

|---|---|---|

Electrical Load Fit | 1–5 | Cross-section suitability for continuous and peak loads. |

Thermal Behavior | 1–5 | Temperature rise limits and cooling requirements. |

Layout Compatibility | 1–5 | Fit within the panel geometry and available space. |

Environmental Suitability | 1–5 | Performance under vibration, moisture, or outdoor exposure. |

Routing Flexibility | 1–5 | Ability to navigate tight bends or dense assemblies. |

Maintenance Access | 1–5 | Ease of inspection, fault isolation, and routine service. |

Future Expansion | 1–5 | Capacity for tap-offs, extensions, or modular upgrades. |

Procurement Fit | 1–5 | Stocking predictability, lead-time stability, and SKU efficiency. |

Total Score

Recommended Range for Strong Fit: 32–40

Acceptable Range for Standard Fit: 24–31

Reassess Below: 23 or lower

Example: A panel shop is evaluating a laminated copper busbar for a compact VFD cabinet.

Scoring Summary

Electrical load fit: 5: Handles continuous and peak currents with low resistance.

Thermal behavior: 4: Maintains stable temperatures in dense enclosures.

Layout compatibility: 5: Flexible layers route cleanly around drives and protective devices.

Environmental suitability: 3: Indoor setting needs only light insulation.

Routing flexibility: 5: Bend-friendly structure supports tight cabinet geometry.

Maintenance access: 4: Fewer joints shorten inspections and fault isolation.

Future expansion: 3: Limited spare capacity allowed in this design.

Procurement fit: 4: Matches standard stocking with predictable availability.

Outcome

Total score: 33 out of 40

Laminated copper performs as a strong fit for compact, heat-sensitive drive cabinets where routing ease and consistency matter.

Once the scoring process becomes familiar, many teams look for guidance during actual projects, so the following section highlights how a technical partner can help.

Partner With ValueAdd for Smarter Busbar Decisions

Choosing the right busbar becomes far easier when a technical partner understands your load demands, panel constraints, and long-term reliability goals. Here is how ValueAdd supports that process with real, application-level expertise.

Why ValueAdd Is the Right Partner:

Expert guidance that aligns busbar selection with load profiles, heat limits, and panel geometry.

Deep product knowledge that helps avoid compatibility issues with drives, breakers, and protection devices.

Territory-based support teams that assist with on-site reviews, panel walkthroughs, and installation questions.

Strong manufacturer relationships that ensure access to reliable, vetted power distribution components.

Practical recommendations that reduce wiring complexity and help standardize builds across OEM or plant projects.

Technical insight that shortens decision cycles for procurement teams working under tight timelines.

Experience across manufacturing, automation, OEM, and industrial facilities that brings context to every specification.

Wrapping Up

A well-chosen busbar can simplify power distribution, improve panel layouts, and support the long-term reliability targets your facility depends on. The concepts covered here provide a clear path for evaluating types, performance factors, and selection criteria with confidence. ValueAdd strengthens those decisions by pairing technical expertise with a deep understanding of real industrial conditions.

Get expert busbar guidance from ValueAdd and move your project forward today

FAQ

What is the purpose of a busbar in electrical systems?

A busbar provides a solid, low-resistance path for distributing power within panels, switchgear, or distribution trunks. Its rigid structure supports higher currents and creates cleaner, more predictable layouts compared to multiple cable runs.

How is a busbar different from a cable?

A busbar handles higher current in a compact form, offers better heat control, and reduces the number of terminations inside a panel. Cables work for flexible routing but become cumbersome and less efficient when loads increase or layouts tighten.

Which material is better for busbars, copper or aluminum?

Copper offers higher conductivity and mechanical strength, making it suitable for demanding industrial loads. Aluminum provides weight and cost advantages for standard applications with controlled environments.

Where are electrical busbars commonly installed?

Busbars appear in MCCs, drive panels, switchgear, riser systems, bus-ducts, data centers, and commercial distribution boards. Their clean routing helps support reliable power flow in environments with tight layouts or high load density.

How do I choose the right type of busbar for my application?

Selection depends on load levels, enclosure space, thermal limits, environmental conditions, and future expansion plans. A structured review of these factors helps match the busbar type to both the electrical and mechanical demands of the project.