What keeps ordinary electrical equipment from becoming an ignition source in environments filled with flammable gasses, vapors, or dust?

In many industrial sites, refineries, chemical plants, grain-handling units, flammable gasses, vapors, or combustible dust may be present. Ordinary electrical equipment (switches, motors, wiring) can become ignition sources under these conditions.

The goal of a Hazardous Area Classification (HAC) is to map out where such explosive atmospheres can form, and how often, so that only suitably rated “explosion-safe” equipment is used there.

When HAC is ignored or done poorly, even a simple spark can lead to fires, explosions, equipment damage, and severe injury or loss of life.

Beyond safety, correct classification also ensures reliability and uptime: appropriately selected equipment reduces incident risks, protects assets, and supports regulatory compliance.

In this blog ahead, we’ll explore how hazardous-area classification is performed, and why it is the cornerstone of safe, compliant, and dependable electrical design in risky industrial environments.

Key Highlights

Hazardous Area Classification (HAC) prevents ignition risks by identifying where flammable gasses or vapors may exist and ensuring only properly rated electrical equipment is installed.

Class I Division 2 areas involve flammable gasses present only in abnormal conditions, such as leaks or equipment failures, requiring non-incendive, sealed, or purged protection methods instead of heavy explosion-proof gear.

C1D2 environments span many industries, including chemical plants, oil & gas sites, wastewater facilities, battery rooms, and manufacturing zones using solvents or alcohol-based materials.

Equipment in C1D2 must be certified and properly sealed, using methods like non-incendive design, purge/pressurization, encapsulation, and increased-safety systems to prevent sparks, heat, or vapor ingress.

ValuAdd provides C1D2-rated components and enclosure solutions that help engineers design safe, compliant, and cost-efficient control systems without over-engineering.

What Are Hazardous Locations?

Hazardous locations are areas where fire or explosion hazards may exist because flammable gases, vapors, liquids, combustible dusts, fibers, or flying particles can accumulate in sufficient amounts. The classification of these areas under recognized standards is critical: it ensures that electrical wiring, instruments, and equipment are chosen and installed so as to avoid ignition sources, thereby protecting people, infrastructure, and business continuity.

Overview of NEC / NFPA 70 and OSHA Requirements

The National Electrical Code (NFPA 70) outlines how hazardous locations are classified and sets installation requirements for safe electrical design in Articles 500–517. It uses Class, Division (or Zone), and Group designations to define the type of hazard and likelihood of its presence.

Class identifies the type of material:

Class I – flammable gasses or vapors

Class II – combustible dust

Class III – ignitable fibers or flyings

Division / Zone describes the frequency of the hazard:

Division 1 / Zone 0-1 – hazard present in normal operation

Division 2 / Zone 2 – hazard present only in abnormal conditions

In the U.S., OSHA enforces compliance with NEC requirements and ensures that only tested and certified equipment is installed in hazardous (classified) locations.

Common Applications and Industries Where Hazardous Locations Exist

Hazardous-location classifications affect a wide range of industries where explosive atmospheres can develop during routine processes. Environments may include flammable storage, dust-generating production, or chemical handling operations.

Examples include:

Oil & gas facilities, refineries, offshore platforms, fuel terminals

Chemical manufacturing & solvent handling areas, paint spray booths

Agriculture & food processing, grain elevators, flour mills, sugar processing.

Woodworking, textiles, and paper mills, where fibers and flyings accumulate.

Fueling stations and hazardous-materials warehouses.

Hazardous locations exist wherever explosive atmospheres may form, and standards such as NEC / NFPA 70 and OSHA regulations provide strict rules for equipment selection and installation.

Understanding the Class I / Division System

The Class I / Division system is a core part of hazardous-location electrical design. It defines risks associated with flammable gasses and vapors and guides the level of protection required for equipment installed in these environments.

What “Class” Means

The Class portion of the classification identifies the type of hazardous substance present in the environment.

Class I applies to locations where flammable gasses, vapors, or liquids may exist in sufficient concentrations to ignite if an ignition source is introduced. These atmospheres are common in facilities that store, transfer, or process fuels, solvents, or volatile chemicals.

Understanding the class ensures electrical design aligns with the specific hazardous material behavior- for example, gas hazards differ from dust hazards and require different protective measures.

What “Division” Means

Division indicates the likelihood or frequency that a hazardous atmosphere will exist under operating conditions.

Division 1 — A flammable gas, vapor, or liquid is present under normal operating conditions, either continuously, intermittently, or periodically. This means ignition risks are routinely possible during day-to-day operations.

Division 2 — Flammable gasses or vapors are not normally present, but may appear only under abnormal conditions, such as equipment failure, leaks, container ruptures, or maintenance activities.

The division classification helps determine the level of protective engineering required, from enclosure types to wiring systems and equipment certification.

Key Differences: Division 1 vs Division 2

Understanding the distinctions between Division 1 and Division 2 is essential for selecting appropriate equipment, designing safe systems, and managing cost-effective engineering strategies in hazardous locations.

Category | Division 1 (C1D1) | Division 2 (C1D2) |

|---|---|---|

Hazard Presence | Present during normal operation | Present only during abnormal events (leaks/failures) |

Risk Level | High/continuous | Lower / occasional |

Equipment Requirements | Explosion-proof or intrinsically safe | Non-incendive, sealed, or purged |

Cost / Complexity | Highest, heavy-duty equipment & strict wiring | Lower, more flexible, and economical |

Installation / Maintenance | Strict sealing, limited access, frequent inspection | Easier installation, routine maintenance |

Typical Use Cases | Fuel loading, open chemical process areas, venting zones | Storage rooms, closed piping systems, battery rooms, compressor skids |

Class I Division 1 vs Class I Division 2

Although both fall under Class I, the difference between Division 1 and Division 2 directly impacts cost, equipment selection, and risk management.

Aspect | Class I Division 1 (C1D1) | Class I Division 2 (C1D2) |

|---|---|---|

Hazard presence | Present under normal conditions | Present only under abnormal conditions |

Risk level | High and continuous/frequent | Lower and intermittent/accidental |

Equipment requirements | Explosion-proof, flame-proof, intrinsically safe | Non-incendive or sealed equipment may be acceptable |

Typical environments | Open process areas, venting zones, and fuel transfer points | Sealed storage, closed piping systems, and monitoring areas |

Cost & design impact | Higher cost and complexity | Lower cost and more flexible layouts |

Correct classification ensures safe operation while avoiding unnecessary cost and over-engineering.

Prevents ignition hazards by aligning equipment protection levels with actual risk

Helps avoid expensive mistakes, such as using explosion-proof gear where it’s not required

Drives regulatory compliance and inspection accuracy

Supports reliability and uptime by reducing failure-related hazards

Enables better maintenance planning, since Division 2 equipment handling may differ from Division 1

Incorrectly downgrading a C1D1 space to C1D2 can create dangerous conditions, while over-specifying C1D2 as C1D1 can inflate project cost without added benefit.

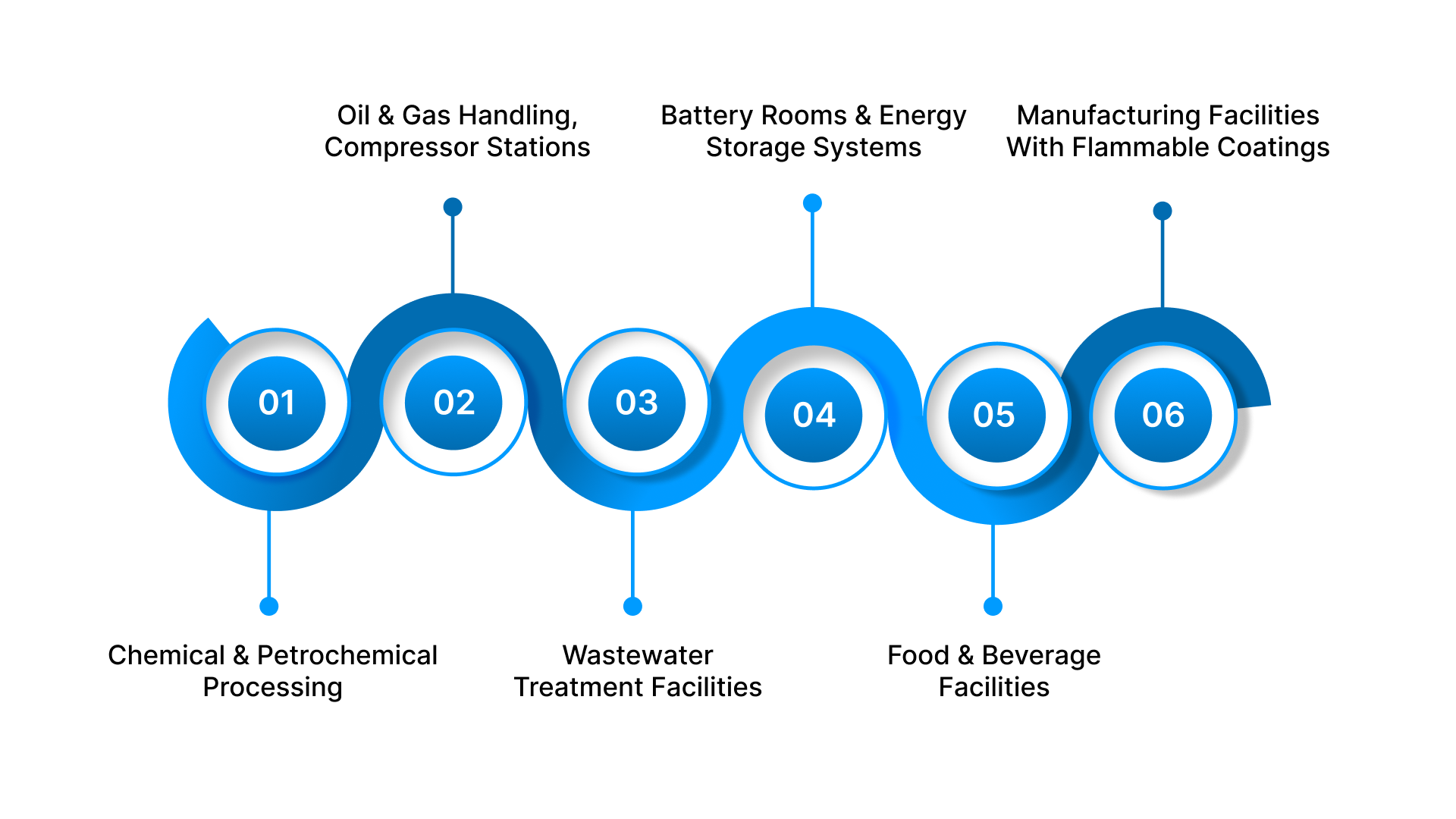

Examples of Class I Division 2 Environments

Class I Division 2 (C1D2) areas are locations where flammable gasses, vapors, or liquids are normally contained within closed systems, but could be released if equipment fails, during maintenance, or due to accidental leakage. Although hazards are not present during routine operation, safety-rated electrical equipment is still required to prevent ignition in abnormal conditions.

Chemical & Petrochemical Processing

Processes involving volatile chemicals often rely on closed piping, tanks, and transfer systems, making many secondary and peripheral spaces C1D2.

Solvent storage rooms, blending systems, reactor service corridors, and packaging areas can be designated C1D2 due to the possibility of vapor escape from valves, pump seals, or transfer connections.

Vent header rooms, scrubber areas, and solvent recovery zones may remain non-hazardous during normal operation but become hazardous if seals fail or equipment ruptures.

Oil & Gas Handling, Compressor Stations & Terminals

Midstream and downstream petroleum operations frequently involve closed-loop gas handling that can release flammable vapors only under abnormal conditions.

Compressor skids, booster pump buildings, meter and regulating stations, and natural-gas dehydration units are commonly classified as C1D2.

Storage and transfer sites for propane, LNG, CNG, or refined fuels often classify pump rooms or manifold areas as C1D2 due to potential leaks or relief-vent discharge.

Wastewater Treatment Facilities

Biological processes generate methane and hydrogen sulfide, which may accumulate in enclosed building spaces under fault conditions.

Digester equipment rooms, sludge-processing buildings, blower rooms, and chemical feed/odor-control facilities are frequently designated C1D2.

Gas handling systems normally contain methane within piping, but failures in seals, pressure controls, or tank covers can create hazardous atmospheres.

Battery Rooms & Energy Storage Systems

Charging and discharging of certain battery chemistries can release hydrogen gas, which is highly flammable even at low concentrations.

Lead-acid and industrial UPS battery rooms, energy-storage containers, and EV charging infrastructure may fall under C1D2 classification when ventilation or monitoring controls are relied upon to maintain safe concentrations.

Hydrogen detection, ventilation logic, and emergency exhaust systems are critical protective measures.

Food & Beverage Facilities Using Alcohol-Based Sanitizers or Solvents

Many modern production and packaging operations rely on volatile organic compounds for sanitation, extraction, or product formulation.

Areas where ethanol, isopropanol, flavor extracts, or botanical processing occurs may become C1D2 depending on storage method and quantity.

Sanitizer filling lines, solvent prep rooms, and packaging stations using alcohol-based sprays represent typical C1D2 scenarios.

Manufacturing Facilities With Flammable Coatings, Adhesives, or Aerosols

Even where spray operations are enclosed or automated, there is a risk of vapor release during abnormal events.

Electronics assembly areas using conformal-coating solvents, furniture finishing lines, automotive repair booths, aerosol filling stations, and adhesive application cells often qualify as C1D2.

Mixing and curing rooms may require ventilation and explosion-rated electrical components to mitigate abnormal-release events.

C1D2 environments are often not visibly hazardous, and equipment is usually closed, ventilated, or contained, but failures can create explosive conditions rapidly.

Equipment Requirements in C1D2 Areas

In Class I Division 2 (C1D2) zones, where flammable gasses or vapors are expected only under abnormal conditions, electrical equipment and enclosures must be selected, installed, and maintained carefully to prevent ignition in case of leaks or accidental release.

Requirements for Electrical Equipment, Control Panels, and Enclosures

Electrical gear used in C1D2 zones must be rated or protected appropriately to avoid becoming an ignition source if a hazardous atmosphere develops.

Equipment installed in C1D2 zones must either be specifically certified for hazardous locations or be enclosed in a suitable protective enclosure rated for hazardous areas.

Control panels, junction boxes, motors, lighting, switches, and wiring systems should meet standards for hazardous-area use. Components that may produce sparks, arcs, or high surface temperature must be avoided or suitably protected.

Enclosures must be robust, sealed (dust/water tight, if relevant), and must maintain appropriate ingress protection (IP) or enclosure rating to prevent ingress of vapors or dust under potential leak conditions.

Sealing, Temperature Control, and Ignition-Source Management

Preventing ignition in a C1D2 zone involves not only certified equipment but also careful control of enclosure integrity, internal/external temperatures, and elimination of potential ignition sources.

Enclosures should be sealed and tight to prevent the entry of flammable vapors. Gaskets, grommets, proper conduit seals, and tight cable entries help maintain a safe barrier.

Surface temperature of equipment parts must not exceed safe limits for expected flammable substances. Heat-producing devices must be appropriately rated or avoided.

Wiring and grounding/bonding must be properly done to avoid static discharge or stray currents, both common ignition sources. All wiring methods should comply with the applicable electrical code for hazardous areas.

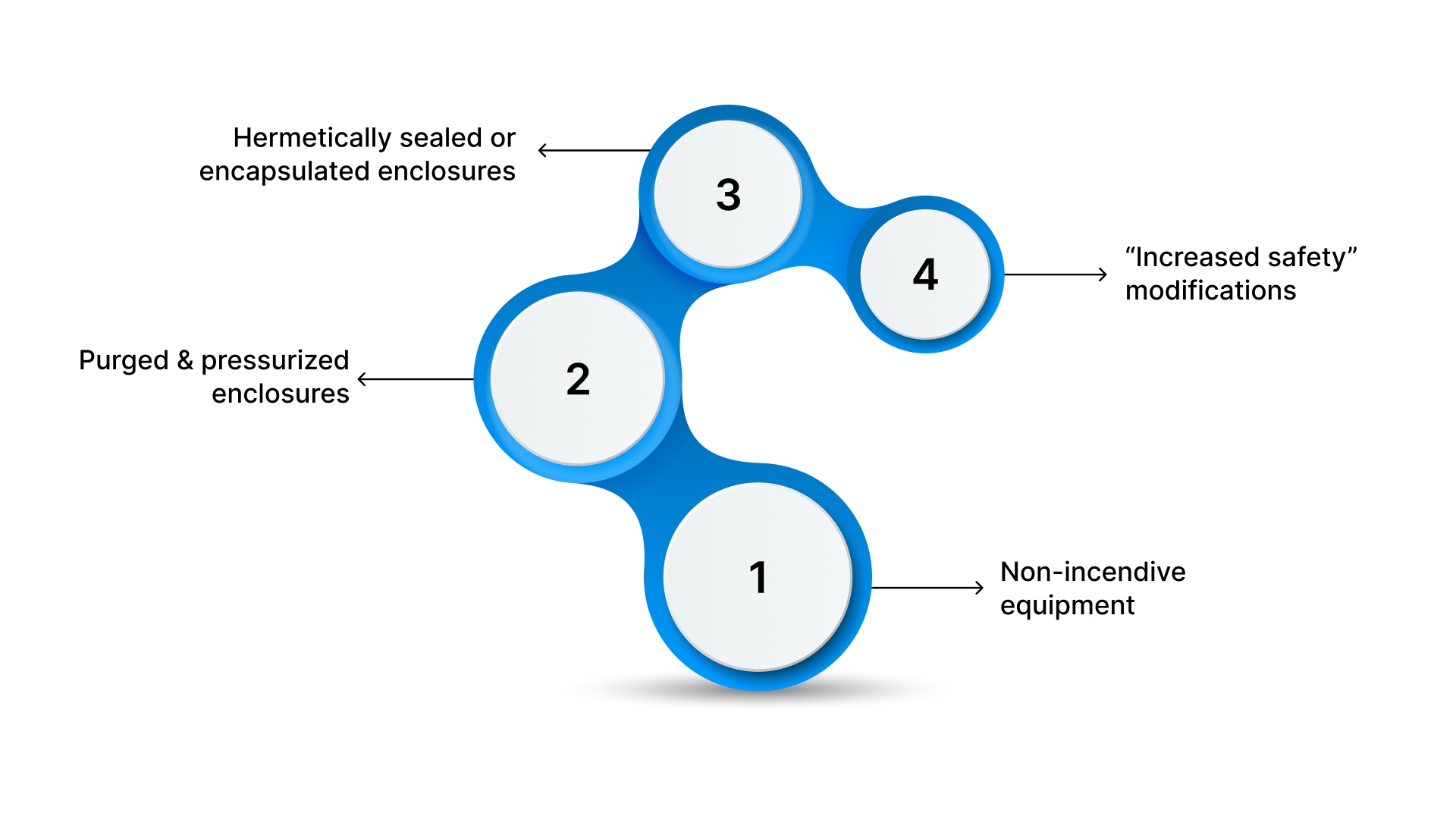

Protection Methods: Non-Incendive, Purge/Pressurization, Increased Safety, Encapsulation

Depending on the application, different protection strategies can be applied, but not all require heavy explosion-proof (flameproof) enclosures.

Common acceptable protection techniques for C1D2 (per U.S. regulations) include:

Non-incendive equipment: Designed such that under normal and specified fault conditions, the energy (spark, heat, arc) is insufficient to ignite a flammable atmosphere. This is often suitable for many Division 2 applications.

Purged & pressurized enclosures (Ex p): The enclosure is purged with clean air or inert gas, removing hazardous vapors, then pressurized slightly to prevent ingress of flammable atmosphere. Standard (non-hazardous-rated) components may be used inside. This technique is defined by standards such as NFPA 496.

Hermetically sealed or encapsulated enclosures: Equipment internals are sealed from the external atmosphere; no venting or openings that allow vapors in. Useful where tight containment is feasible.

“Increased safety” modifications: Equipment designed to reduce the chances of arc/spark, restrict temperature rise, and avoid internal sparking contacts. Often used in lower-risk hazardous zones.

Importantly, heavy explosion-proof “flameproof” enclosures (common in Division 1) are not always necessary for Division 2. Over-specifying protection can add cost and complexity without additional safety benefit.

Common Components & Solutions Used in C1D2 Systems

Class I Division 2 systems rely on specialized equipment designed to operate safely where flammable gasses or vapors may be present under abnormal conditions.

Control Panels & Enclosures Listed for C1D2

Control panels installed in C1D2 areas must be built and certified to prevent ignition risk if a flammable atmosphere occurs.

Enclosures are often UL/CSA-listed for Class I Division 2 or built using purge/pressurization systems to allow use of standard industrial components inside.

Typical designs include sealed or gasketed construction, ventilation control, and ingress protection ratings such as IP66 / NEMA 4X.

Features may include intrinsically safe barriers, cable glands with sealing requirements, and thermal management to control surface temperature.

Applications: motor control centers, pump stations, compressor controls, chemical dosing or batching systems, process skids.

Relays, Monitoring Devices, Switches & PLC Hardware

C1D2-rated electrical and automation components ensure that control and monitoring systems can safely remain powered and operational.

Includes relays, contactors, terminal blocks, isolators, power supplies, intrinsically safe I/O modules, and remote I/O racks.

PLC platforms often include C1D2-certified chassis, modules, and communication components, allowing safe installation without flameproof housings.

Arc and spark-producing devices are engineered or protected so they remain non-incendive under normal and specified fault conditions.

Purged & Pressurized Enclosures with Climate Control

Purge/pressurized panels enable the use of non-hazardous-location equipment inside a hazardous area by preventing vapor ingress.

Type Z or X purge systems supply clean air or inert gas to maintain positive internal pressure.

Enables installation of standard PLCs, VFDs, servo drives, networking hardware, or industrial computers inside hazardous zones.

May include active cooling/heating equipment such as hazard-rated air conditioners, vortex coolers, heat exchangers, or filtered fan systems to control temperature and humidity.

Remote Operator Interfaces & Industrial HMIs

Remote operator workstations allow interaction with process equipment without exposing electronics to hazardous atmospheres.

Designed for hazardous environments using sealed touchscreens, fiber-optic networking, and low-energy signaling.

Options include C1D2-certified HMIs, panel-mount interfaces, intrinsically safe tablets, and remote display stations.

Used for pump skid control, chemical dispensing, batching operations, compressor management, and material handling systems.

UPS, Power Conditioning & Motor Control Systems

Power and motor-control components must maintain safety and reliability during abnormal events, including power failures or emergency shutdowns.

C1D2-rated UPS systems, power converters, and transformers provide backup without generating ignition-capable energy levels.

Motor control designed for hazardous environments may include C1D2 starters, overload protection devices, soft starters, and VFDs when suitable protection methods are applied.

Ground-fault detection, surge suppression, isolation transformers, and overload relays help prevent sparks or overheating.

By combining properly rated components, sealed control equipment, and specialized protective techniques, facilities can achieve safe, compliant, and high-uptime operation in hazardous industrial settings.

Practical Guidelines for Engineers and Safety Professionals

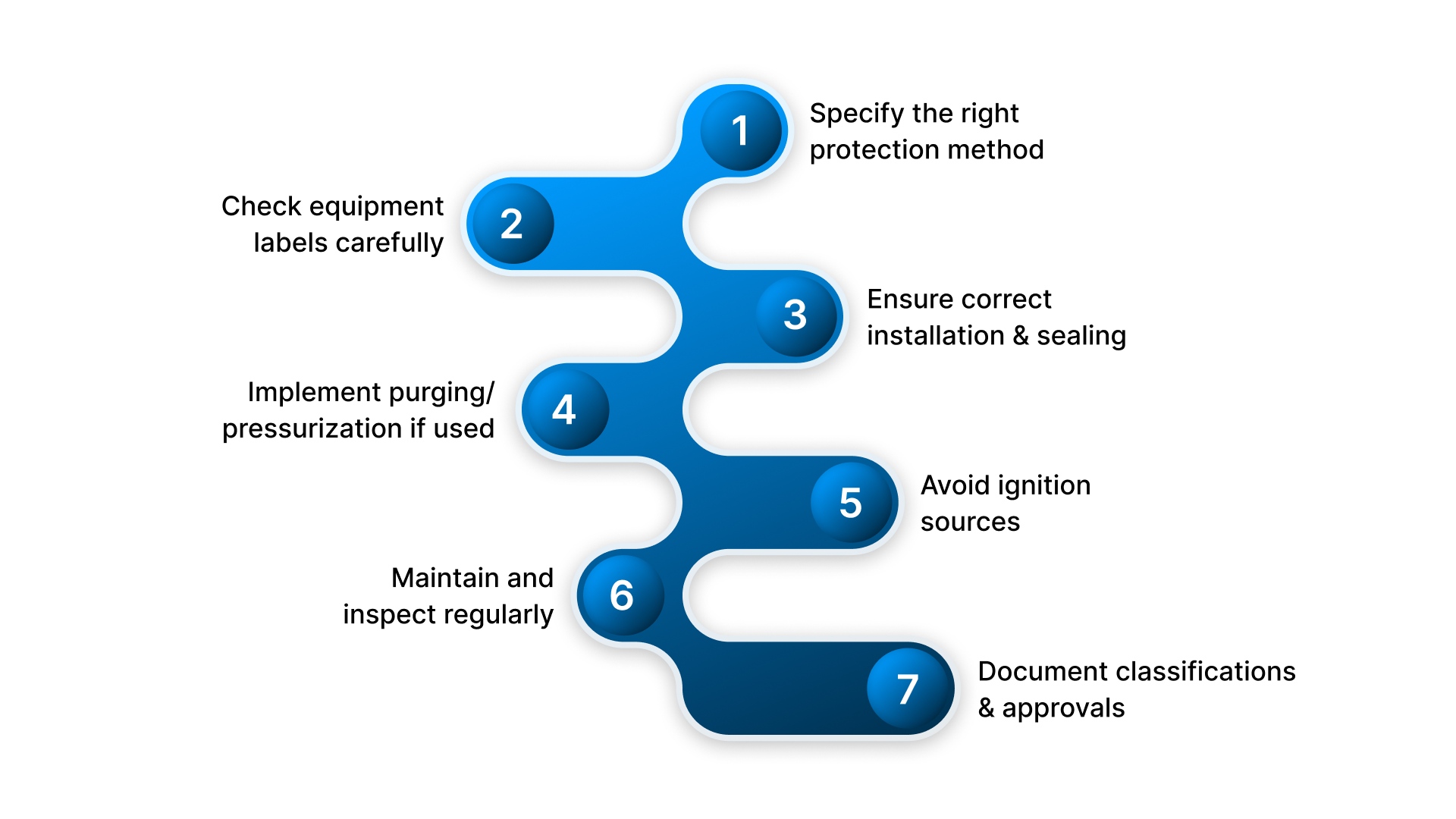

To ensure safe installation and operation in C1D2 areas, follow these guidelines:

Specify the right protection method — match Class/Division and likely hazards, rather than defaulting to “explosion-proof” everywhere.

Check equipment labels carefully — confirm Class I Division 2 (or equivalent), gas Group, temperature rating, and certified protection type.

Ensure correct installation & sealing — use appropriate conduit seals, gaskets, and maintain enclosure ingress-protection (IP) or NEMA rating.

Implement purging/pressurization if used — with clean/inert gas, maintained overpressure, venting/flow control, alarms, or interlocks if pressure is lost.

Avoid ignition sources — minimize heat, arcs, sparks; ensure proper grounding/bonding and avoid non-rated components.

Maintain and inspect regularly — especially after maintenance or process changes; leaks or degraded seals can convert a “safe” zone into a hazardous one.

Document classifications and approvals — maintain records of area classification, equipment certifications, wiring diagrams, maintenance checklists, and inspection history.

ValuAdd C1D2 Components for Safe Hazard-Area Control

Industrial control systems built for Class I, Division 2 environments rely on components that meet demanding safety, reliability, and environmental performance standards.

Saginaw Control & Engineering – Industrial steel and stainless enclosures for hazardous and corrosive environments; suitable for purged/pressurized control panels

Fibox – Polycarbonate non-metallic enclosures for chemical facilities, outdoor classified sites, and washdown environments

Benshaw – Motor control and soft-start solutions engineered for C1D2 applications and heavy-duty industrial loads

Socomec / Boltswitch / NOARK – Switching, disconnect, and circuit protection components for hazardous-rated electrical distribution

CIMON – Class I Division 2-certified PLCs, remote I/O, and industrial HMIs for automation and control systems

Macromatic / Finder – Monitoring, timing, protection, and control relays designed for hazardous-location safety logic

TCI – Power-quality hardware and harmonic mitigation solutions supporting VFD-intensive hazardous environments.

How These Solutions Integrate Into C1D2 System Designs

ValuAdd delivers field-tested solutions across South Carolina, North Carolina, and Virginia, supporting OEM equipment, panel shops, automation projects, and industrial facility upgrades.

Commonly used in OEM skid packages, process equipment, compressor/pump systems, and chemical dosing skids.

Enable UL-listed C1D2 control panel architecture with compliant switching, motor control, automation, protection, and enclosure solutions

Support standardized and scalable bill-of-materials strategies for panel builders and distributors.

Improve uptime, simplify code compliance, and reduce engineering complexity in hazardous industrial applications.

Conclusion

Correct hazardous-location classification and thoughtful equipment selection are essential to meeting NEC safety requirements and preventing ignition risks in environments where flammable gasses or vapors may be present. Choosing properly rated Class I Division 2 components enables safe, reliable, and code-compliant operation without unnecessary cost or the over-engineering associated with Division 1 protection methods.

C1D2-optimized solutions allow engineers, OEMs, and panel builders to balance safety, system performance, and project budget, especially when supported by clear documentation, coordinated planning, and informed product selection early in the design process.

ValuAdd provides engineering-focused support and access to proven C1D2 component solutions that help customers design reliable hazardous-location control systems with confidence. Connect with a ValuAdd expert for tailored recommendations.

Frequently Asked Questions (FAQ)

1. Who determines hazardous area classification?

Area classification is defined by engineers, safety teams, and AHJs using standards like NEC (NFPA 70) and OSHA regulations. It is typically documented in drawings and confirmed by inspection.

2. What types of electrical equipment can be used in C1D2 areas?

Equipment must be listed or approved for Class I Division 2, such as non-incendive devices, sealed components, purge/pressurized enclosures, and C1D2-certified PLCs, HMIs, relays, and power hardware.

3. Do all devices in a C1D2 area need explosion-proof enclosures?

No, explosion-proof designs are typically required for Division 1. C1D2 allows non-incendive or sealed equipment, reducing cost and complexity while maintaining safety.

4. What are T-codes and why are they important?

T-codes specify the maximum surface temperature a device can reach. Selecting the correct T-code ensures equipment will not ignite hazardous vapors if released.

5. Can standard VFDs and drives be used in C1D2 locations?

Yes, when appropriately protected using harmonic filters, reactors, or housed in purged/pressurized enclosures. Power-quality components help maintain reliability.