Could your new industrial plant survive one spark? In the high-stakes world of hazardous-gas facilities and heavy-duty automation, even a tiny electrical fault can turn into a disaster, unless the right enclosure is protecting your equipment.

Global demand for hazardous-area enclosures is booming: the market, valued at US $1.5 billion (2024), is projected to expand to around US $2.5 billion by 2032.

That growth reflects more than just booming industrialization that it speaks to safety, compliance, and peace of mind. Properly selected enclosures, especially Class 1 Division 2 (C1D2)-rated boxes, are becoming mission-critical components across OEM machines, industrial automation lines, and municipal facilities. These enclosures ensure that flammable gasses or vapors, combustible dust, or stray sparks don’t trigger destructive explosions.

In environments where regulatory compliance, personnel safety, and uninterrupted operation are non-negotiable, the enclosure housing your electricals isn’t just another box, and it’s your first line of defence.

Key Highlights

C1D2 zones handle flammable gasses that appear only under abnormal conditions (like leaks or equipment failure), making certified enclosures essential for preventing ignition risks.

Special C1D2 enclosures stop sparks, arcs, heat, or internal faults from igniting hazardous vapors, ensuring safe operation without the cost of full explosion-proof systems.

Compliance with NEC, UL, CSA, ATEX, and IECEx standards is mandatory, and using non-rated internal components instantly voids the enclosure’s hazardous-location certification.

Material, construction, T-codes, sealing, and thermal management are critical to choosing the right enclosure, preventing overheating, condensation, or gas ingress.

ValuAdd strengthens C1D2 system design by offering certified enclosures, non-incendive components, automation hardware, and engineering support to ensure safety, compatibility, and long-term reliability.

What Is a Class I Division 2 Area?

Under the National Electrical Code (NEC) classification scheme, hazardous-area designations are broken down first by Class and then by Division (or Zone).

Class I refers to locations where flammable gasses, vapors, or liquids might be present in the air at concentrations sufficient to form explosive or ignitable mixtures.

Within Class I, two divisions are defined to indicate how often a hazardous atmosphere is likely to occur:

Division 1 — hazardous gasses or vapors are present under normal operating conditions (continuously, intermittently, or periodically).

Division 2 — hazardous gasses or vapors are not normally present. They may appear only under abnormal conditions, such as a leak, equipment failure, or containment breach.

Thus, a Class I Division 2 (C1D2) location is one in which flammable gasses or vapors are typically confined (e.g., in closed containers or closed systems) and do not exist in ignitable concentrations during regular operation, but could escape and pose a hazard if something goes wrong.

What “Abnormal Conditions” Mean

“Abnormal conditions” that might trigger a hazardous atmosphere in a Division 2 area often include:

A leak or rupture in a closed container or sealed piping system holding a flammable liquid or gas.

Failure of a ventilation or exhaust system, allowing vapors or gasses to accumulate.

Maintenance, repair, or other non-routine operations that disturb the sealed system or containers.

Under normal operation, the assumption is that these systems remain intact and flammable substances remain contained, so the probability of a dangerous atmosphere is low. But the classification acknowledges that risk cannot be ignored entirely, hence special precautions are mandated.

Why This Classification Matters: Equipment & Safety

Classifying an area as C1D2 has direct implications for the selection of electrical equipment, enclosures, and safety measures. Some of the key requirements and safeguards include:

Use of certified equipment: Electrical devices installed must be certified for Class I Division 2 service, meaning they’re designed to prevent sparks or surface temperatures from igniting flammable atmospheres, and even if gasses or vapors are unexpectedly released.

Proper enclosures: Enclosures (junction boxes, control panels, enclosures around electrical components) must meet stringent standards to contain any internal ignition and prevent hazardous atmosphere ingress.

Temperature control and ventilation: Equipment must not exceed safe surface temperatures. Adequate ventilation (or explosive-atmosphere mitigation) is needed to avoid the buildup of flammable gsases or vapors.

Maintenance and operational vigilance: Since the hazard is conditional, regular inspection of containers, seals, piping, and ventilation systems is critical. Any leakage or failure must be addressed promptly to prevent a hazardous atmosphere.

This means that even though a C1D2 area may seem low-risk during normal operations, the potential for an incident under abnormal conditions demands rigorous design, guarding, and maintenance practices.

Real-World Examples of Class I Division 2 Environments

C1D2 classification commonly applies to industrial settings where flammable materials are used, stored, or processed but normally kept sealed. Some typical examples include:

Chemical or petrochemical plants: Storage tanks or piping systems containing flammable liquids/gasses where occasional leaks (e.g., due to valve failure) could release vapors.

Refineries or utility gas facilities: Areas where volatile gasses or LPG / natural gas are handled in closed systems, e.g., inside a control room, pipe-rack gallery, or filling area, where under normal operation no free vapor is present, but a leak might occur.

Industrial automation machines and OEM equipment: Enclosures and control panels in plants where flammable vapors might escape only during maintenance, container rupture, or accidental release, not during normal operation.

Auxiliary rooms or utility areas adjacent to more active hazard zones: Sometimes C1D2 classification is used for buffer or support zones where vapors are not expected under normal conditions but might appear if adjacent systems fail.

This classification matters because it drives the selection of certified equipment, explosion-resistant enclosures, proper ventilation, and strict maintenance regimes to avoid the rare but potentially catastrophic ignition of a hazardous atmosphere.

Why Special Enclosures Are Required

In hazardous industrial environments, electrical enclosures serve far more purposes than providing mechanical protection.

Preventing Ignition Sources in Potentially Explosive Atmospheres

In Class I Division 2 classifications, flammable gasses or vapors may be present only under abnormal conditions. In such environments, any spark, electrical arc, or excessive surface temperature can trigger an explosion. Special hazardous-area enclosures are therefore designed to:

Eliminate or control ignition sources that could ignite flammable atmospheres.

Contain and cool internal ignition events, preventing flames and hot gasses from escaping.

Maintain safe surface temperatures even under electrical failure or overload.

By containing ignition internally rather than allowing it to escape, these enclosures protect surrounding environments from catastrophic chain-reaction events.

Protecting Controls, Power Components & Automation Hardware

Modern industrial systems rely on advanced automation, sensors, PLCs, networking hardware, and power distribution components, all of which require reliable protection. Hazard-rated enclosures provide:

Environmental protection against moisture, dust, corrosive chemicals, vibration, and mechanical impact.

Secure wiring and terminal management to prevent loose connections or arcing.

Extended operational life and reduced failure rates for critical equipment.

In industries where downtime equals lost production or safety risk, protection against environmental damage is just as critical as explosion protection.

Supporting Safety, Reliability & Regulatory Compliance

Specialized hazardous-area enclosures also play a crucial role in meeting safety and compliance requirements. They enable facilities to:

Meet national and international standards (NEC, IECEx, ATEX, UL/cUL listings, etc.).

Protect personnel and infrastructure by reducing exposure to high-risk electrical faults.

Avoid fines, shutdowns, and liability associated with non-compliant installations.

Maintain continuous operation with lower maintenance and fewer unplanned stoppages.

Compliance is not simply an administrative obligation, and it is directly tied to safety culture, operational performance, and risk management.

Key Requirements for Class I Division 2 Enclosures

Class I Division 2 (C1D2) enclosures must meet strict engineering and certification requirements to ensure they can safely operate in environments where flammable gasses or vapors may be present only under abnormal conditions. The following elements define what qualifies an enclosure for C1D2 installations.

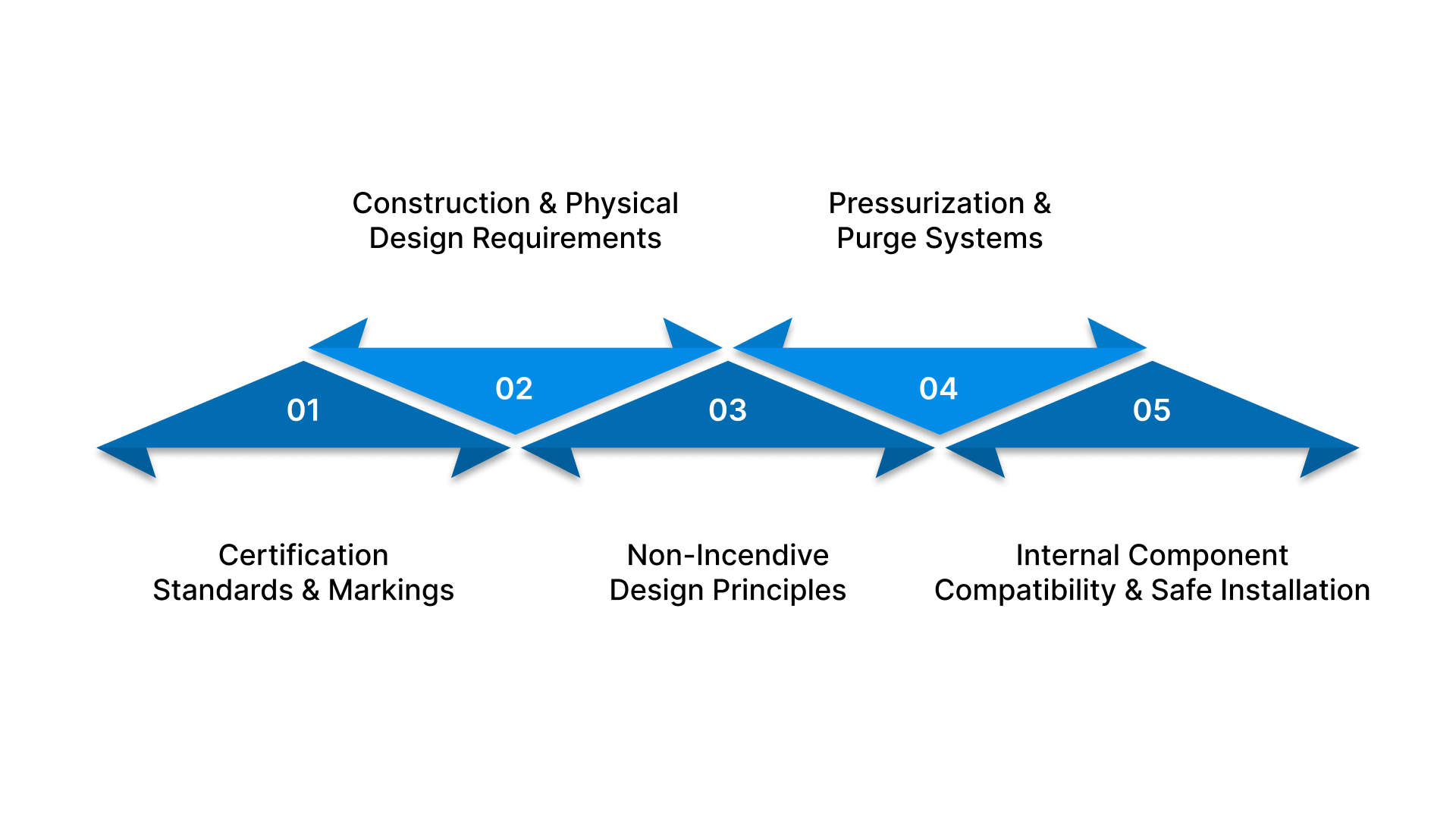

Certification Standards & Markings

To ensure safety and legal compliance, C1D2 enclosures must carry recognized third-party certifications. Common required standards include:

UL (Underwriters Laboratories) — UL 50E / UL 1203 for hazardous-location equipment.

CSA (Canadian Standards Association) — C22.2 standards for electrical equipment in explosive atmospheres.

ATEX (EU Directive 2014/34/EU) — Required for equipment used in explosive atmospheres in Europe.

IECEx — International voluntary certification aligning with IEC 60079 standards.

Certification labels typically include:

Class I, Division 2 location rating

Gas group (e.g., Group B, C, D)

Temperature code (T-rating) indicating maximum surface temperature

Relevant file numbers and approval agency mark

Construction & Physical Design Requirements

C1D2 enclosures must be engineered to survive industrial abuse while preventing the entry of hazardous gasses. Key construction elements include:

Material strength & corrosion resistance (stainless steel, aluminum, engineered polymers)

Ingress protection (commonly IP66/NEMA 4 or 4X) for dust, water, and chemical exposure

High-performance gasketing and sealing to maintain internal isolation

Temperature tolerance & thermal management to ensure safe surface temperatures under load

Mechanical durability to withstand vibration, shock, and pressure changes

These features prevent explosive atmospheres from reaching internal components and reduce the likelihood of internal failures becoming ignition sources.

Non-Incendive Design Principles

For Division 2 environments, equipment must be designed so that under normal operation and some abnormal fault conditions, it cannot produce sufficient energy to ignite an explosive atmosphere. This includes:

No exposed arcs, sparks, or hot surfaces

Protected or sealed connectors

Controlled wiring layouts reduce the risk of insulation failure

Limited internal stored energy (capacitance/inductance management)

Non-incendive circuits and components are essential when using sensors, terminals, and control electronics inside C1D2 enclosures.

Pressurization & Purge Systems (When Required)

Some higher-risk applications require pressurization (Ex p / NFPA 496) enclosures, which use clean air or inert gas to maintain internal pressure above external atmospheric conditions. This prevents hazardous gasses from entering the enclosure.

Pressurization systems typically include:

Automatic pressure monitoring and alarms

Purge cycles before power-up

Venting and safe discharge paths

These are common for large control cabinets, HMIs, VFDs, servers, and electronics with ignition-capable components.

Internal Component Compatibility & Safe Installation

Even a properly certified enclosure can become unsafe if internal components are not compatible. Critical considerations include:

T-Codes (Temperature ratings) to ensure all components stay below ignition temperatures for the gasses present

Spacing and creepage distances to minimize arcing and insulation breakdown

Wiring and cable gland suitability for hazardous-area installations

Management of potential ignition sources such as relays, power supplies, and switching devices

Proper grounding and bonding to eliminate static charge buildup

Every component within the enclosure must support the overall safety rating, and certification is invalid if incompatible parts are installed.

Types of Enclosures Used in C1D2 Applications

Various enclosure types are used to meet the performance, durability, and safety requirements of Class I Division 2 environments. Selection depends on application needs such as corrosion resistance, environmental exposure, mounting style, and internal hardware requirements. Common enclosure categories include:

Steel and stainless-steel enclosures designed for harsh industrial conditions and corrosive environments, offering high mechanical strength and excellent protection against physical impact, temperature extremes, and chemical exposure.

Polycarbonate and other non-metallic enclosures are used where lightweight construction, UV resistance, and protection from outdoor weather or aggressive chemical atmospheres are essential, while maintaining C1D2 certification.

Modular, wall-mount, floor-standing, and machine-mount enclosure configurations supporting flexible installation in OEM machinery, automation cells, skid systems, control rooms, and distributed field equipment.

Standard sealed enclosures vs. purged/pressurized enclosure systems, where purged/pressurized designs are required for equipment that contains ignition-capable components or generates heat, using controlled internal positive pressure to prevent flammable gas ingress.

Common Mistakes to Avoid

Even well-designed hazardous-area installations can become unsafe or non-compliant if critical details are overlooked. These are some of the most frequent and costly mistakes seen in Class I Division 2 applications:

Assuming any NEMA 4X enclosure automatically meets C1D2 requirements, even though environmental protection ratings (NEMA/IP) do not guarantee hazardous-location certification.

A NEMA 4X enclosure may resist water and corrosion, but it is not inherently designed to prevent ignition or contain internal faults unless specifically marked and certified for Class I Division 2.

Mixing non-rated or uncertified internal components inside a C1D2 enclosure invalidates the enclosure’s hazardous-location certification. Even with a properly rated enclosure, internal switches, relays, power supplies, connectors, and wiring must be compatible with C1D2 requirements to ensure non-incendive operation.

Ignoring temperature class (T-code) requirements leads to components that exceed allowable surface temperatures for the hazardous gas group involved. Selecting the wrong T-rating can create ignition risk even when other protections are in place.

Overlooking ventilation, thermal loading, and condensation concerns can result in overheating, internal corrosion, and electrical failure. Enclosures in high-temperature or humid environments may require heat dissipation design, venting, thermal analysis, or pressurization to maintain safe operation and prevent moisture accumulation.

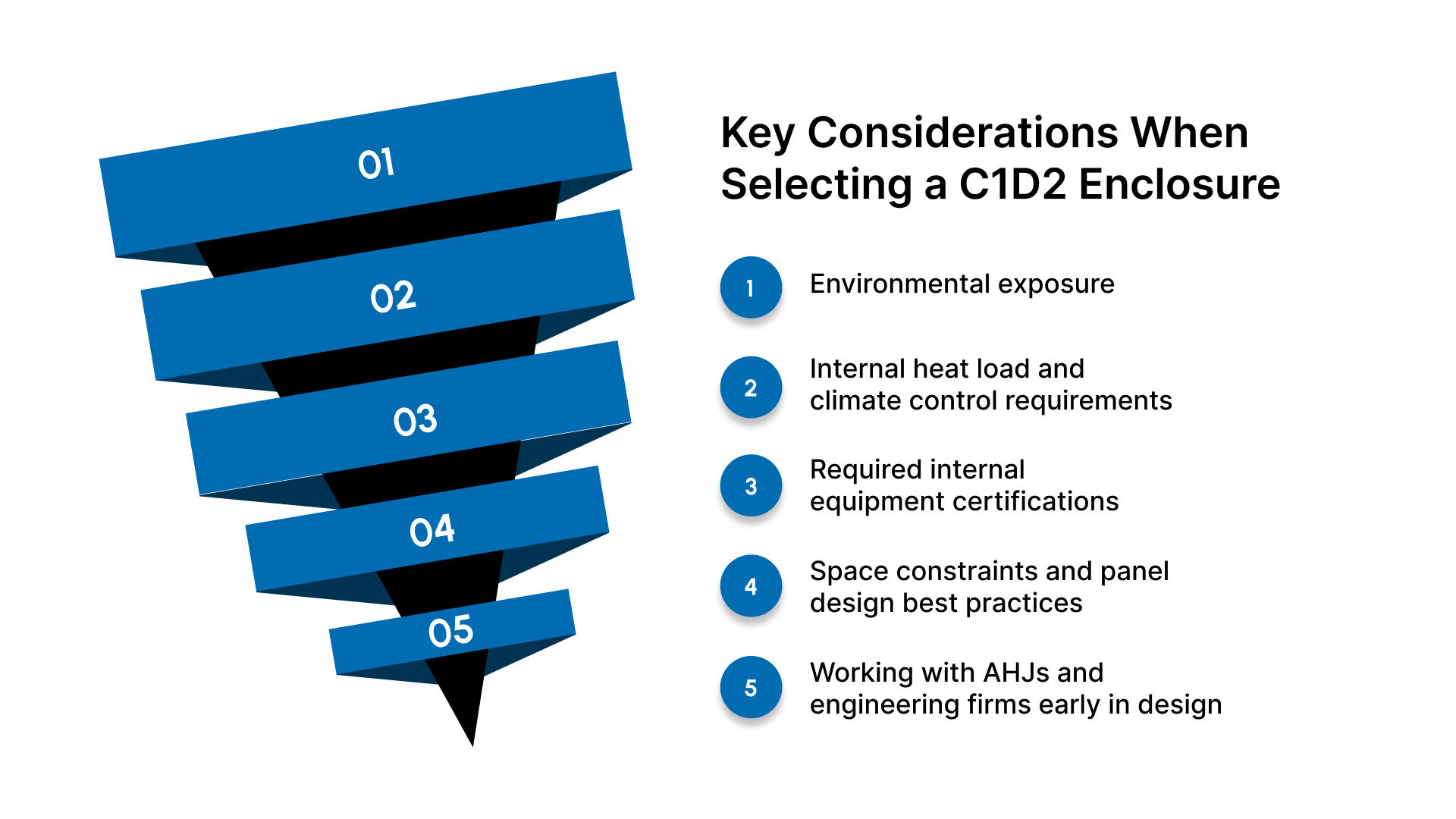

Key Considerations When Selecting a C1D2 Enclosure

Selecting the right Class I Division 2 enclosure requires understanding environmental, technical, and compliance factors that influence long-term safety and performance. Key considerations include:

Environmental exposure, including ambient temperature, humidity, corrosion, outdoor UV resistance, and washdown or chemical contact conditions, along with appropriate NEMA/IP ratings.

Internal heat load and climate control requirements, assessing heat generated by internal components and determining the need for cooling, ventilation, heat exchangers, insulation, or condensation management.

Required internal equipment certifications, ensuring all devices inside the enclosure meet C1D2 or non-incendive rating requirements, including proper T-codes, wiring methods, and cable glands.

Space constraints and panel design best practices, allowing for heat dissipation, wiring access, maintenance clearance, modular expansion, and avoiding overcrowding that increases failure and overheating risk.

Working with AHJs and engineering firms early in design, collaborating with compliance experts and authorities to align interpretations of code, confirm approvals, and avoid redesign delays or installation non-compliance.

ValuAdd Advantages That Strengthen C1D2 System Design & Deployment

Delivering safe, compliant, and reliable Class I Division 2 solutions requires more than selecting the right enclosure, and it requires technical guidance, compatible components, and coordinated system-level support. A ValuAdd approach helps OEMs, panel builders, and industrial facilities design smarter, standardize equipment, and reduce risk in hazardous-location environments.

Access to rugged steel, stainless, and non-metallic enclosure platforms designed for corrosive, outdoor, and industrial conditions, including options compatible with purge/pressurization and climate-control systems.

Availability of motor control hardware, switching devices, protection components, and disconnect solutions suitable for hazardous-area panel builds and industrial reliability requirements.

Support for automation platforms, including PLCs, HMIs, and control hardware that integrate safely within C1D2 enclosures for OEM machinery, municipal upgrades, and distributed control systems.

Wide range of relays, monitoring devices, panel components, and supporting hardware engineered for safe non-incendive circuit design and long-term performance.

Ability to standardize complete C1D2 control system packages using complementary product lines that reduce complexity, improve compatibility, and simplify sourcing.

Local application and technical support that assists engineers with proper specification, thermal management, wiring considerations, and certification alignment for hazardous locations.

Solution collaboration with panel shops, OEMs, and consulting engineers to streamline enclosure selection, design reviews, and compliance with NEC, UL, and hazardous-area standards.

Conclusion

Properly selecting a Class I Division 2 enclosure is essential for safety, code compliance, and long-term equipment performance. The right C1D2 solutions enable safe, reliable operation in hazardous environments without the expense and complexity of full explosion-proof systems, making them an ideal choice for OEM equipment, industrial automation, and municipal infrastructure.

Early engineering alignment and careful component selection significantly reduce project risk, prevent redesign, and ensure certification success from the start.

ValuAdd provides application guidance, component selection help, and complete support for hazardous-location panel design. Contact us today to discuss your project and get expert assistance.

Frequently Asked Questions (FAQ)

1. Do all NEMA 4X enclosures qualify for C1D2?

No. NEMA/IP ratings only address environmental protection, not ignition prevention. An enclosure must be specifically certified and labeled for C1D2 use.

2. Why are special enclosures required for C1D2 applications?

They prevent internal faults from creating sparks, arcs, or excessive surface temperatures that could ignite flammable atmospheres.

3. Can standard electrical components be used inside a C1D2-rated enclosure?

Only if they are certified for C1D2 or non-incendive use. Mixing non-rated components can void compliance and create safety risks.

4. What is the role of temperature codes (T-codes)?

T-codes define the maximum safe surface temperature of equipment. Using an incorrect T-rating may cause ignition even inside a certified enclosure.

5. When are purge/pressurization systems required?

They are used for larger cabinets or electronics that generate heat or could produce ignition sources—maintaining safe internal pressure to prevent gas ingress.