Faced with legacy control panels or new machine builds, selecting between a contactor-only setup and a full motor starter becomes a critical decision; a wrong choice can lead to unplanned downtime, motor burnout, or maintenance headaches. A clear understanding of how each device functions helps ensure system reliability and lower lifecycle costs. In the United States, electric motors still account for roughly 70 % of industrial electricity consumption, underlining how common and critical motor-driven systems remain.

Quick Overview

A contactor handles power switching only, making it suitable for small or steady-load motors that already have overload protection from a breaker, VFD, or soft starter.

A motor starter combines a contactor with overload protection, making it the safer choice for pumps, conveyors, compressors, and any motor that can stall, overheat, or affect production if it fails.

Contactor-only setups fit low-risk equipment where downtime has little impact, while starters fit equipment that drives throughput, sees load swings, or must avoid automatic restarts after a fault.

The device you choose influences motor lifespan, fault response, trip behavior, maintenance time, and how predictable your system remains under real operating conditions.

What Is a Contactor?

A contactor is an electrically operated switch that lets you control power to a motor or another heavy load without adding built-in protection. It helps simplify control wiring when your protection already exists upstream through breakers, drives, or external relays. In many panels, a contactor becomes the go-to choice when the load is low-risk, and the goal is fast, reliable switching.

Some applications demand more than switching alone, so it’s worth looking at when a motor starter provides safer, more dependable results.

What Is a Motor Starter?

A motor starter combines a contactor with overload protection so you can control and safeguard a motor in one device. The overload section helps prevent damage during abnormal current conditions, which reduces the likelihood of unplanned downtime. Many OEMs and panel shops prefer starters because they offer consistent protection across machines and simplify maintenance.

With both devices defined, it becomes easier to put them side by side and see how their functions differ in real operating conditions.

Key Differences Between a Contactor and vs Motor Starter

A contactor handles switching, while a motor starter adds the protection needed to keep a motor safe during abnormal conditions. A clearer view of how each component functions in real applications helps guide better decisions, so here are the core differences in a simple, skimmable table.

Factor | Contactor | Motor Starter |

|---|---|---|

Primary Function | Switches power on/off | Switches power and protects the motor |

Protection Included | None (requires external devices) | Built-in overload protection |

Reliability Impact | Depends on upstream protection | Reduces risk of motor damage |

Best Use Cases | Low-risk loads, existing protection, simple panels | Industrial motors, critical machines, standardized builds |

Safety & Compliance | Must be paired with protection to meet standards | More likely to satisfy protection requirements |

Maintenance Burden | Higher if the load varies or the protection is inconsistent | Lower due to integrated protection elements |

Panel Standardization | Minimal | Supports repeatable, consistent panel builds |

Knowing the technical differences is helpful, but applying them in real projects requires recognizing the situations where a contactor is actually enough.

When to Use a Contactor Only?

A contactor fits well when the application needs reliable switching, and your protection is already handled elsewhere in the system. To help you decide during panel design, upgrades, or troubleshooting, here are the situations where a contactor-only setup makes practical sense:

Low-stress loads where overload events are unlikely in normal operation

Motors already protected by correctly sized breakers, drives, soft starters, or external overload relays

Systems requiring rapid or frequent switching without adding extra components

Panels where space is tight, and adding protection devices complicates wiring or layout

Simple start/stop applications that do not require coordinated motor protection

Machines where a motor failure would not affect critical throughput or production deadlines

Facilities that centralize protection at the feeder level and follow a coordinated protection strategy

Projects where reducing component cost is part of the design goal without compromising safety

Some applications demand more than switching alone, so it’s worth looking at when a motor starter provides safer, more dependable results.

When Is a Motor Starter the Right Choice?

A motor starter becomes a safer and more reliable option when your application needs both switching and built-in overload protection. To guide your decisions in critical environments or new builds, here are the conditions where a motor starter delivers clear operational advantages:

Motors supporting production lines where downtime creates measurable output loss

Applications with fluctuating load conditions that increase the risk of overheating

OEM machines, where consistent, repeatable protection simplifies engineering and long-term support

Panels designed to meet compliance expectations for overload, short-circuit, and voltage-loss protection

Retrofit projects where older contactor-only circuits need safer, updated protection

Plants with lean maintenance teams that benefit from integrated protection that speeds troubleshooting

Installations where preventing automatic restarts after faults is essential for safety

Projects aiming to reduce lifecycle costs by preventing premature motor failures through proper protection

Understanding where each device fits sets the stage for seeing how the choice affects long-term reliability, maintenance, and motor performance.

Operational Impact on Motors

Choosing the right device directly influences motor life, system stability, and the risk of production-stopping failures. To make the operational effects easier to evaluate during design or troubleshooting, here are the impacts that matter most, organized in clean nested bullet points:

Motor Protection and Longevity

Proper overload protection helps your motor avoid thermal stress that leads to early failure.

Stable protection settings support consistent motor behavior across varying loads.

Reduced overheating incidents limit insulation damage and extend overall service life.

Downtime and Maintenance Requirements

Integrated protection in a starter lowers the chance of sudden shutdowns during unexpected load conditions.

Clear trip indications allow your maintenance team to diagnose issues faster.

Fewer motor failures reduce emergency repair calls and unplanned downtime.

System Stability and Performance

Coordinated protection helps prevent nuisance trips triggered by voltage dips or fluctuating loads.

Consistent motor operation supports predictable throughput on production lines.

Better stability reduces the chance of one failure triggering problems in connected systems.

Cost and Lifecycle Planning

Lower failure rates keep replacement costs and spare parts needs under control.

Predictable motor behavior simplifies long-term maintenance planning across machines.

Improved reliability supports more accurate budgeting for upgrades and future projects.

Since the impact on equipment can vary widely, a simple decision checklist makes it easier to choose the right device for your specific setup.

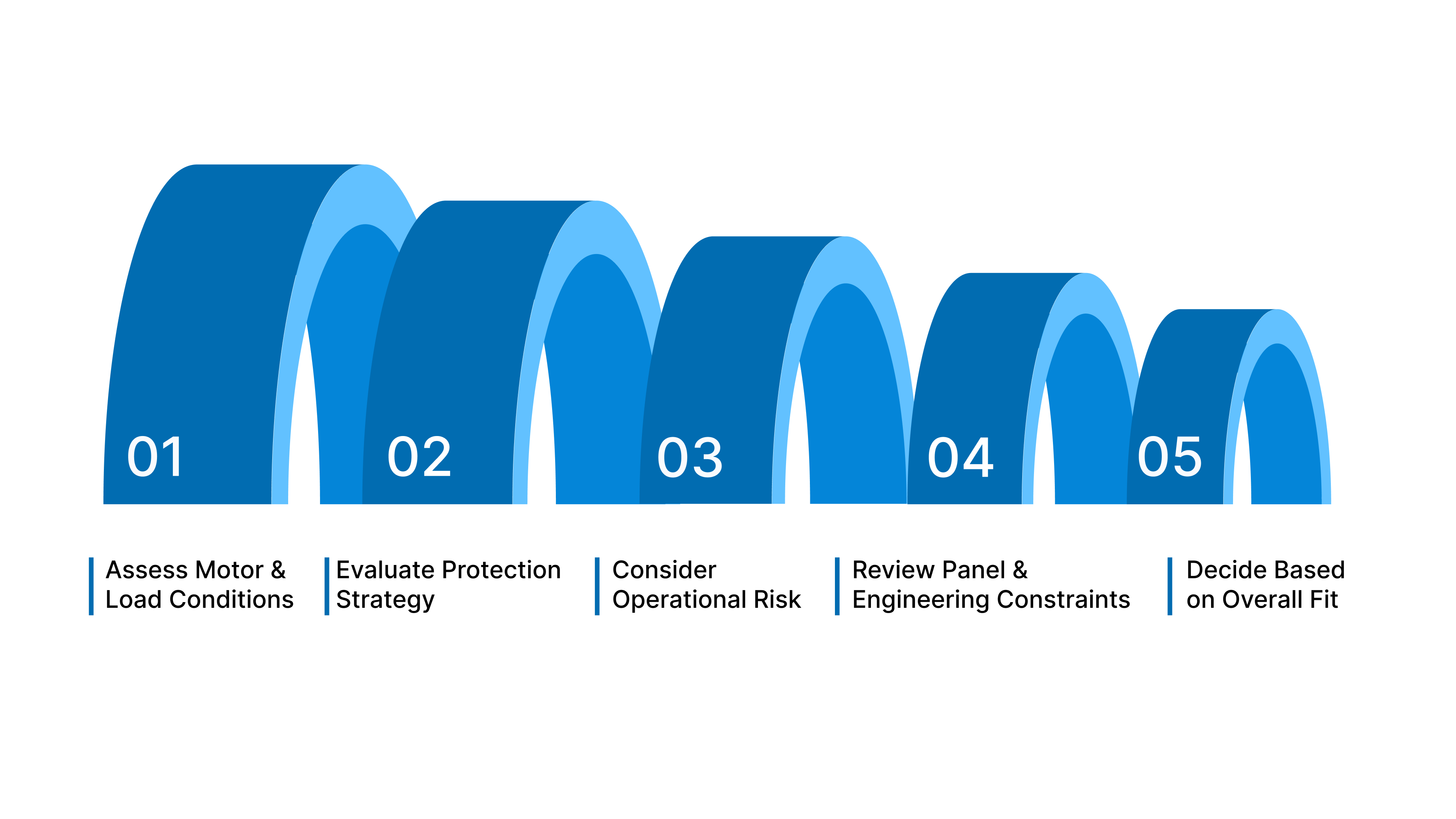

How to Choose the Right Option?

Selecting between a contactor and a motor starter becomes easier when the decision is based on load behavior, protection needs, and the operational risk tied to a motor failure. To help guide your evaluation during design, troubleshooting, or standardization work, here’s a practical checklist you can use:

Assess Motor & Load Conditions

Determine the motor’s load type (steady, variable, or high-inertia).

Check how often the motor starts, stops, or cycles under normal operation.

Identify whether overheating or overload events are likely in your environment.

Evaluate Protection Strategy

Confirm if upstream devices already provide overload protection.

Check coordination with breakers, drives, or soft starters.

Determine if added protection is required to comply with internal or project standards.

Consider Operational Risk

Estimate the impact of a motor failure on production throughput or service continuity.

Identify whether downtime creates safety concerns or delays.

Assess how quickly maintenance can respond if a failure occurs.

Review Panel & Engineering Constraints

Check panel space, wiring complexity, and layout requirements.

Determine whether standardizing on starters simplifies BOMs and repeat builds.

Evaluate how each choice affects spare parts planning and stock levels.

Decide Based on Overall Fit

Contactor-only if protection exists elsewhere and the risk is low.

Motor starter with integrated protection reduces downtime, simplifies support, or aligns with compliance expectations.

Support from a team that understands real operating conditions, like the specialists at ValueAdd, can make this decision far easier for your engineering or maintenance group. Even with a solid checklist, common mistakes still happen in the field, so reviewing these pitfalls can help prevent issues during installation or upgrades.

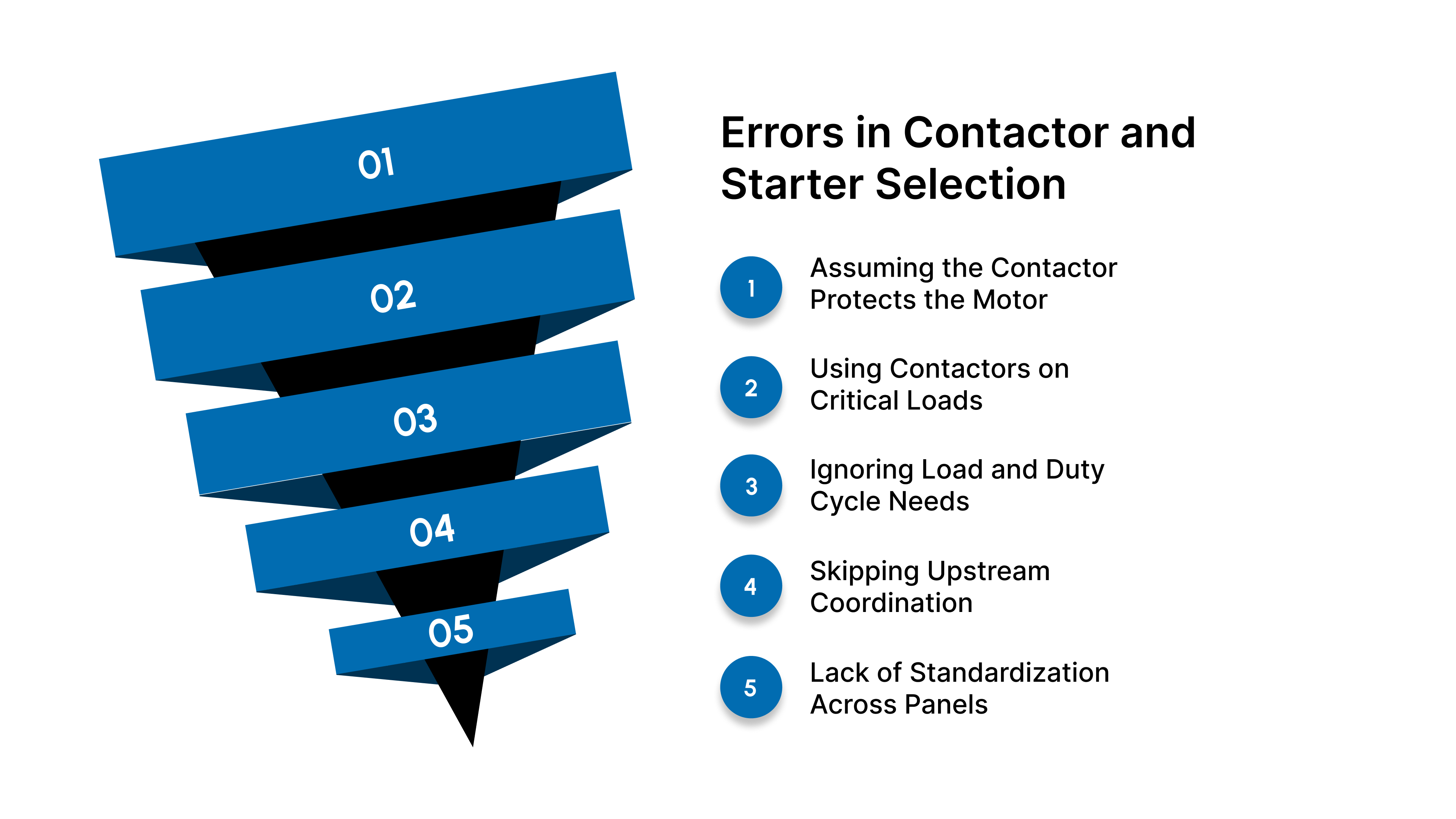

Common Errors in Contactor and Starter Selection

Choosing between a contactor and a motor starter can lead to issues when the decision is based on assumptions instead of load behavior and protection needs. To make the risks clearer during design or troubleshooting, here are the most common errors engineers and panel teams encounter:

Assuming the Contactor Protects the Motor

Many systems run into trouble when the contactor is treated as a full protection device rather than a switch. This leads to overload risks that shorten motor life and increase failure rates. Clear separation between switching and protection helps prevent unexpected shutdowns.

Using Contactors on Critical Loads

Critical motors often need the added safety and reliability provided by a starter. Relying on a contactor-only setup increases downtime risk when loads support production or essential processes. Matching protection to the motor’s importance strengthens overall system stability.

Ignoring Load and Duty Cycle Needs

Motor behavior under real conditions determines how much protection is required. Loads that vary or start frequently create stress that a contactor alone cannot manage. Aligning the device with the actual operating profile prevents repeated trips and premature wear.

Skipping Upstream Coordination

Improper coordination between breakers, drives, or fuses can cause nuisance trips or missed faults. Each device must work within the same protection strategy to maintain stability. Proper coordination ensures the motor responds predictably during abnormal events.

Lack of Standardization Across Panels

Inconsistent hardware choices make maintenance and spare parts planning more difficult. Standardization helps teams support equipment faster and reduce lifecycle costs. A unified approach also improves troubleshooting during unplanned failures.

Once these risks are understood, it becomes easier to see where expert guidance can support better decisions and reduce future problems.

Get Expert Help Choosing Between a Contactor or a Starter

Making the right choice becomes far easier when a technical partner understands your load conditions, protection needs, and the operational risks tied to each motor. To highlight how ValueAdd supports stronger decisions in motor-control design, here are the ways their team helps you get this right:

Technical guidance on whether a contactor-only setup or a full starter fits your application

Support in evaluating load behavior, duty cycle, and protection gaps that affect motor reliability

Component-selection expertise backed by a curated portfolio of industrial-grade manufacturers

On-site or territory-based assistance to review panels, upgrade paths, and protection strategies

Advice grounded in real industrial environments, not generic catalog descriptions

Integration insights that help your components work together with fewer coordination issues

Reliable access to products backed by trusted manufacturer relationships

Support that reduces downtime risk and speeds decision-making for OEMs, plant teams, and panel shops

Wrapping Up

Understanding the difference between a contactor and a motor starter gives you clearer control over reliability, protection, and long-term motor performance. Stronger decisions at the component level reduce downtime, strengthen safety, and support more predictable operation across your systems. ValueAdd brings the technical depth, product knowledge, and real-world application insight needed to make these decisions with confidence.

For expert help with motor-control selection, coordinated protection strategies, or component compatibility, contact ValueAdd for technical support and application-specific guidance.

FAQ

What Is the Main Difference Between a Contactor and a Motor Starter?

A contactor handles switching, while a motor starter adds overload protection to keep a motor safe during abnormal conditions. This difference affects reliability, uptime, and how well the system handles varying loads.

Can a Contactor Run a Motor Without a Starter?

A motor can run with a contactor alone if overload protection is provided elsewhere in the system. Without proper protection, the motor is exposed to overheating and failure risks during abnormal current conditions.

When Should a Motor Starter Be Used Instead of a Contactor?

A motor starter is the better choice for motors supporting critical equipment, varying loads, or applications where downtime carries operational or safety consequences. Built-in overload protection helps prevent damage and keeps the system stable.

Does a Contactor Provide Any Overload or Short-Circuit Protection?

A contactor does not provide overload or short-circuit protection. Additional devices such as overload relays, breakers, or drives must be used to protect the motor and maintain compliance with electrical safety requirements.

Is a Motor Starter Required for All Motor Applications?

Not all motors require a starter, especially when upstream devices already provide coordinated protection. Applications with stable loads, low risk, or integrated protection through VFDs or soft starters may use a contactor-only setup without compromising safety.