Unplanned downtime in manufacturing systems can cost businesses up to $260,000 per hour on average, a staggering amount that impacts production efficiency, customer satisfaction, and profit margins.

For engineers and OEMs, the stakes are high when it comes to system design, safety, and ensuring reliable operation. Proper electrical control and fail-safe systems are essential to avoid costly failures. This is where a well-chosen Normally Closed (NC) contactor plays a vital role.

NC contactors provide a default “closed” state, offering reliability, safety, and power continuity when needed. In this guide, we’ll walk you through how NC contactors work, why they are indispensable for reliable system design in control panels, and how selecting the right contactor can significantly reduce downtime and improve overall system safety.

Key Takeaways

NC Contactors Work by Defaulting to a Closed Circuit: When de-energized, the contacts remain closed, allowing current to flow. Energizing the coil opens the circuit, interrupting the flow.

Fail-Safe and Safety-Critical: NC contactors are ideal for safety circuits, emergency stop systems, and backup power circuits, ensuring power remains until a shutdown signal or fault condition occurs.

Difference Between NO and NC Contactors: Normally Open (NO) contactors keep circuits off until triggered, whereas NC contactors maintain a closed circuit by default and only open under specific conditions.

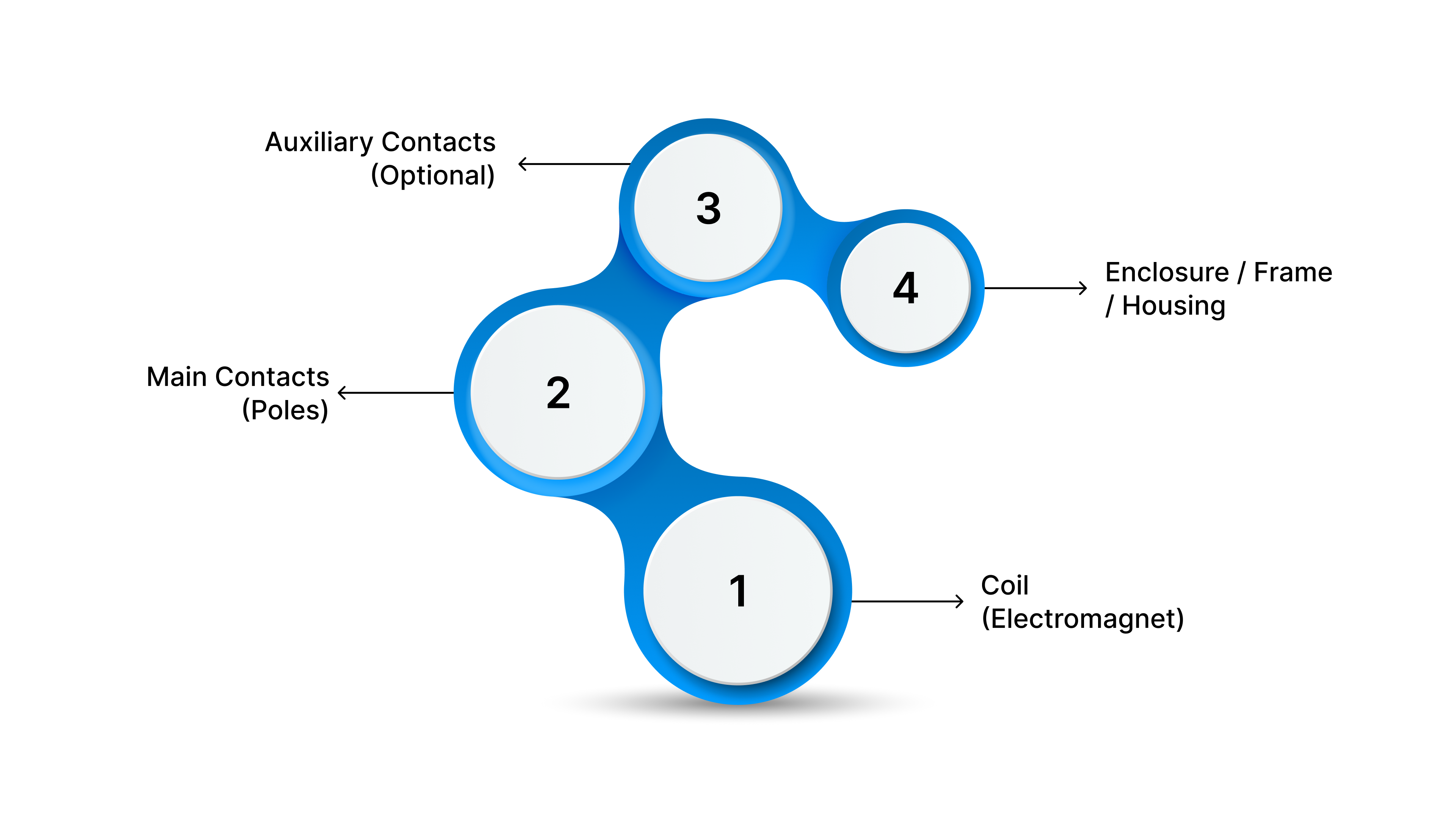

Core Components of NC Contactors: Key elements include the coil (electromagnetic actuator), main contacts (which open or close the circuit), auxiliary contacts (for control logic), and the enclosure that houses and protects the components.

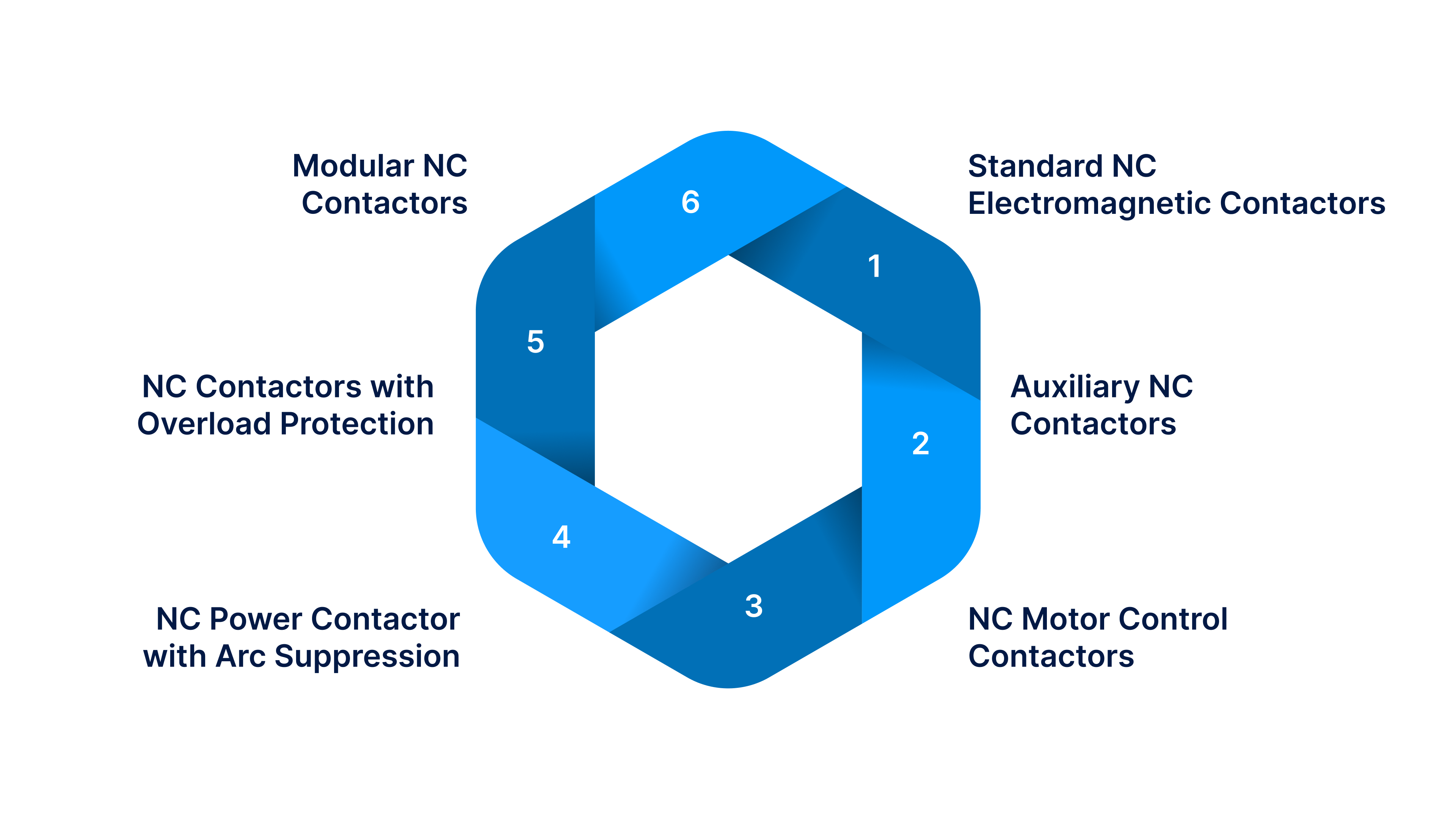

Types of NC Contactors: NC contactors vary based on use, from standard electromagnetic types to those with overload protection, arc suppression, and modular designs for complex systems.

What is a Normally Closed Contactor?

A Normally Closed (NC) Contactor is an electromechanical switching device where the contacts are closed (conducting) when the coil is de-energized. The circuit remains complete by default.

When the coil is energized, the contacts open, interrupting the circuit. NC contactors are used in industrial and motor control applications where fail-safe operation is critical, allowing a system to stay powered until a specific condition triggers the opening of the contacts, such as an emergency stop or safety shutdown.

NC contactors are often used in safety circuits, emergency stop systems, or applications where controlled power interruption is needed.

Key Features of NC Contactors

Understanding the features of Normally Closed (NC) Contactors is important, as they play a critical role in fail-safe designs, making sure that power stays on until safety conditions, like an emergency stop, are triggered. This helps prevent equipment damage and provides worker safety.

Default closed circuit when coil is de‑energized: In its normal (no‑power) state, an NC contactor’s contacts remain closed, so current flows through the circuit by default.

Opens circuit when coil is energized: When you energize the coil, the moving contact retracts and opens the circuit, interrupting current flow.

Handles high‑power loads: As with any contactor, NC contactors can switch high currents/voltages, suitable for motors, pumps, HVAC, lighting, and other industrial loads.

Electromechanical actuation: They use an electromagnetic coil to move contacts, allowing remote or automated control of heavy‑duty loads through low‑voltage control circuits.

Auxiliary contact / control‑circuit flexibility: Many contactors allow auxiliary contacts (NO or NC) alongside main contacts. This lets engineers integrate control logic, interlocks, or safety circuits along with main power switching.

Configurable for safety or fail‑safe applications: Because NC contactors close circuits by default, they are especially suited for safety circuits, emergency‑stop paths, backup‑power circuits, or systems requiring power continuity until a shutdown signal.

These features stem from a straightforward electromechanical process. The mechanism behind NC contactors explains why they behave the way they do.

Basic Working Principle of a Normally Closed Contactor

The Normally Closed (NC) contactor ensures continuous power flow until a specific condition, like an emergency stop, interrupts the circuit. This fail-safe operation is essential for designing reliable and safe systems in motor control, safety circuits, and industrial automation.

Coil and Contacts: NC contactors consist of a coil made of copper wire wound around a core, paired with a set of contacts.

Electromagnetic Actuation: When electrical current flows through the coil, it generates a magnetic field that moves the contacts.

Contact Movement: For NC contactors, this movement separates the contacts, opening the circuit.

Reverts to Closed: When the coil is de-energized (power is removed), the contacts return to their default closed position, restoring the circuit.

This feature makes NC contactors ideal for applications where power continuity is crucial, as it ensures circuits stay closed until a specific condition triggers an interruption.

ValuAdd supplies industrial-grade power-distribution, metering, monitoring, and protection components through trusted manufacturers such as Socomec. We help you specify the right components for your systems and provide guidance on correct specification, integration, or panel-ready control hardware through our full brand portfolio.

Applications of Normally Open (NO) Contactors Across Industries

Normally Open (NO) contactors are widely used in industrial applications to control motors, lighting, HVAC systems, and more, by activating power only when needed. Their ability to reduce energy consumption and improve control makes them essential for efficient system operations.

Motor Control in Manufacturing & Machinery: NO contactors power motors, pumps, conveyors, or compressors by closing circuits only when needed. They make “start‑on‑demand” control simple, avoiding continuous draw when idle.

Lighting & HVAC Systems in Commercial / Institutional Facilities: For large lighting installations, heating/cooling systems, or HVAC units, NO contactors act as reliable remote switches that activate loads only upon command (e.g, when a thermostat or lighting controller triggers them).

Industrial Equipment & Automation Systems: Machinery, presses, welding equipment, and other heavy loads are often switched with NO contactors so that power is supplied only when control logic demands it, reducing unnecessary energy use.

Power‑Management and Utility Switching: NO contactors help manage power distribution, lighting banks, and distribution circuits in commercial and industrial power panels, enabling centralized control over multiple high‑power circuits.

While NO contactors excel in start-on-demand scenarios, choosing the right contactor type for your application requires understanding how NO contactors differ in their default states and operational behavior.

Difference Between Normally Opened and Normally Closed Contractors

When selecting a contactor for industrial applications, understanding the difference between Normally Open (NO) and Normally Closed (NC) contactors is crucial. These two types of contactors serve distinct purposes depending on how they behave when the coil is energized or de-energized.

Feature / Behavior | NO (Normally Open) Contactor | NC (Normally Closed) Contactor |

Default contact state (coil de‑energized) | An open circuit is disconnected / no current flows | Closed circuit is connected / current flows by default |

State when the coil is energized | Contacts close, circuit becomes conductive. | Contacts open, circuit is interrupted / power removed |

Typical use/application logic | To switch power ON when triggered, e.g, “start‑on‑demand”, motor start, lighting, and non‑safety circuits | To maintain power until deactivated; e.g, safety interlocks, emergency‑stop, fail‑safe shutdowns, default‑on loads |

Behavior on loss of control signal/coil power | Circuit stays open; load OFF (safe for non‑critical loads) | Circuit returns to default closed, load remains powered (fail‑safe or standby) |

Both contactor types share fundamental building blocks, though they function differently. Breaking down these components shows what drives their distinct behaviors.

Core Components in an NC Contactor

Any contactor, including an NC contactor, comprises a few fundamental building blocks. Understanding these helps when you specify or evaluate a device.

Coil (Electromagnet)

This is the control element. When energized (or de‑energized, depending on configuration), it actuates the contacts. The coil determines the control/circuit voltage needed and influences reliability under different supply conditions.

Main Contacts (Poles)

These are the actual current‑carrying contacts that open or close the power circuit. For NC contactors, the “normal” (de‑energized) state keeps contacts closed, and energizing the coil breaks the circuit.

Auxiliary Contacts (Optional)

These are additional contacts (NO or NC) used for control logic, signaling, interlocks, or control‑circuit feedback. Even if the main contacts are NC, auxiliary contacts may be used for NO/NC logic in control wiring

Enclosure / Frame / Housing

Provides mechanical support, insulation, mounting means, and protection against environmental hazards (dust, moisture, mechanical shock) depending on application requirements.

These components work together to deliver specific advantages in real-world applications. The benefits of NC contactors become clear when matched to the right use cases.

Benefits of Normal Closed Contractors in Various Applications

Normally closed (NC) contactors are essential in applications where power continuity and safety are crucial. They remain closed by default and only open under specific conditions, making them ideal for fail-safe environments.

Safety: NC contactors keep the circuit closed until a specific trigger opens it, making them critical for safety circuits and emergency shutdowns.

Fail-Safe Operation: If control signals are lost or power is interrupted, NC contactors remain closed, maintaining the circuit.

Reliability: NC contactors provide consistent power flow until a shutdown condition occurs, making them ideal for motor control, lighting, and backup systems.

Prevents Unintended Shutdowns: The default closed position minimizes the risk of accidental disconnection in safety-sensitive applications.

Simplicity: NC contactors have a simple operation, making them easy to integrate into systems without complex control logic.

Automation: Widely used in industrial automation, they keep systems active until an intentional shutdown command or fault condition occurs.

Different applications demand different contactor configurations. Manufacturers have developed several NC contactor variants to address specific industrial requirements.

Types of NC Contactors Based on Use and Design

Normally closed (NC) contactors come in various designs, each tailored to specific industrial applications. Their primary function remains the same: to keep the circuit closed by default, but their design and features vary to suit different power loads, control systems, and environmental conditions.

Standard NC Electromagnetic Contactors

These are the most common types of NC contactor, where the main contacts are normally closed (i.e., they remain closed when the coil is de-energized) and open when the coil is energized.

Auxiliary NC Contactors

These are used as auxiliary or additional contacts within a larger system, providing NC behavior for control circuits, signaling, or interlocking applications.

NC Motor Control Contactors

These are specifically designed for controlling motor circuits, where NC contacts are used to provide fail-safe behavior, particularly for emergency stop or safety shutdown functions.

NC Power Contactor with Arc Suppression

These contactors are designed for use in high-voltage or high-current systems and include features to suppress arcs, protecting the contactor from damage and improving its durability. They are often used in heavy-duty industrial environments.

NC Contactors with Overload Protection

Some NC contactors come integrated with overload protection, which is ideal for preventing equipment damage in case of overcurrent conditions, such as in industrial motor control circuits.

Modular NC Contactors

These are customizable contactors, often used in complex systems where additional features such as auxiliary contacts, thermal protection, or communication interfaces are required. They may include NC contact elements as part of the modular configuration.

Why ValuAdd is Your Trusted Partner for Industrial Electrical Solutions?

At ValuAdd, we are more than just a manufacturer’s representative agency. We position ourselves as a technical solutions partner, helping you specify and integrate the right combination of industrial electrical components, from contactors and motor controls to enclosures and power quality solutions.

Wide Product Range: We represent a variety of products from trusted manufacturers such as Noark, Benshaw, Hedla, and American Electrical. Our portfolio includes contactors, motor controls, enclosures, and automation hardware.

Application Support: We assist in selecting the right components, ensuring compatibility, and helping avoid specification errors.

Streamlined Procurement: By offering multiple product lines under one roof, we simplify sourcing and reduce complexity.

Local Expertise: With our deep understanding of regional industrial needs such as NC, SC, and Virginia, we provide reliable, tailored solutions for your control and power distribution systems.

Efficiency: We reduce the need to deal with multiple manufacturers, making your procurement process more efficient.

We focus on providing expert guidance to ensure you get the best products for your systems, eliminating the complexity of dealing with multiple suppliers.

Conclusion

The vital role of Normally Closed (NC) contactors in maintaining continuous power flow, safety, and reliability in industrial applications. Their fail-safe design makes them essential for motor control, emergency shutdown systems, and automation, helping prevent unplanned downtime and enhance overall system safety. Understanding their working mechanism and appropriate application allows engineers and OEMs to design systems that prioritize safety, reliability, and operational continuity.

ValuAdd is your trusted partner in delivering industrial‑grade electrical solutions. With experience across 6 key industries, we offer a 100% technical focus, providing expert application support and sourcing solutions for your control and power distribution needs.

Connect with our industrial electrical experts to get the right components for your next project.

FAQs

Which is safer, NO or NC?

NC contactors are generally considered safer for fail-safe applications since they keep the circuit closed by default, ensuring power remains until a specific trigger interrupts the flow, such as in emergency stop or safety shutdown systems.

How do I choose the right NC switch?

When selecting an NC switch, consider factors such as the voltage and current rating, coil voltage, load type, environmental conditions, and whether the switch needs to integrate into a safety or control circuit to ensure reliability and performance.

What are the two basic types of contactors?

The two basic types of contactors are normally open (NO) and normally closed (NC). NO contactors allow current to flow only when energized, while NC contactors maintain current flow by default and open when energized.

How to tell if a contactor is NO or NC?

To identify if a contactor is NO or NC, check the default position of the contacts. If the contacts are closed when the coil is de-energized, it’s an NC contactor; if they’re open, it’s an NO contactor.

What is the use of an NO NC contactor?

NO and NC contactors are used to control electrical circuits in industrial systems. NO contactors are typically used to start or stop a circuit, while NC contactors are used in applications that require a fail-safe operation, such as emergency shutdowns or safety systems.