In modern manufacturing environments, even a small control‑system failure can bring an entire production line to a grinding halt, and the cost of such downtime is staggering.

According to a recent industry survey, unplanned outages now cost many industrial operations roughly US $125,000 per hour on average. That means a single faulty push‑button switch or mis-specified control panel component could silently erode hundreds of thousands in revenue before anyone even notices.

For engineers and plant managers trying to maintain uptime, this risk isn’t abstract; it’s a recurring threat to productivity, delivery schedules, and profitability.

In this blog, we’ll walk you through the different push button switch types, show you where each type fits best, and explain the key specifications to check, so you can avoid unreliable controls, prevent unexpected downtime, and build strong, reliable control systems right from the start.

Key Takeaways

Push-Button Operation: Push-button switches open or close circuits to control current flow, with momentary or maintained actions depending on the design.

Types of Push-Button Switches: NO (Normally Open) and NC (Normally Closed) switches serve different roles, such as activation or deactivation, and emergency stops.

Switch Configurations: SPST, SPDT, DPST, and DPDT offer varying levels of control, from simple on/off to managing multiple circuits or outputs.

Important Specifications: Voltage, current ratings, IP protection, mechanical endurance, and compliance certifications are crucial for reliable and safe switch performance.

Applications: Push-button switches are used in industrial machinery, safety systems, control panels, electronics, and critical infrastructure, offering versatile control solutions.

What is a Push-Button Switch?

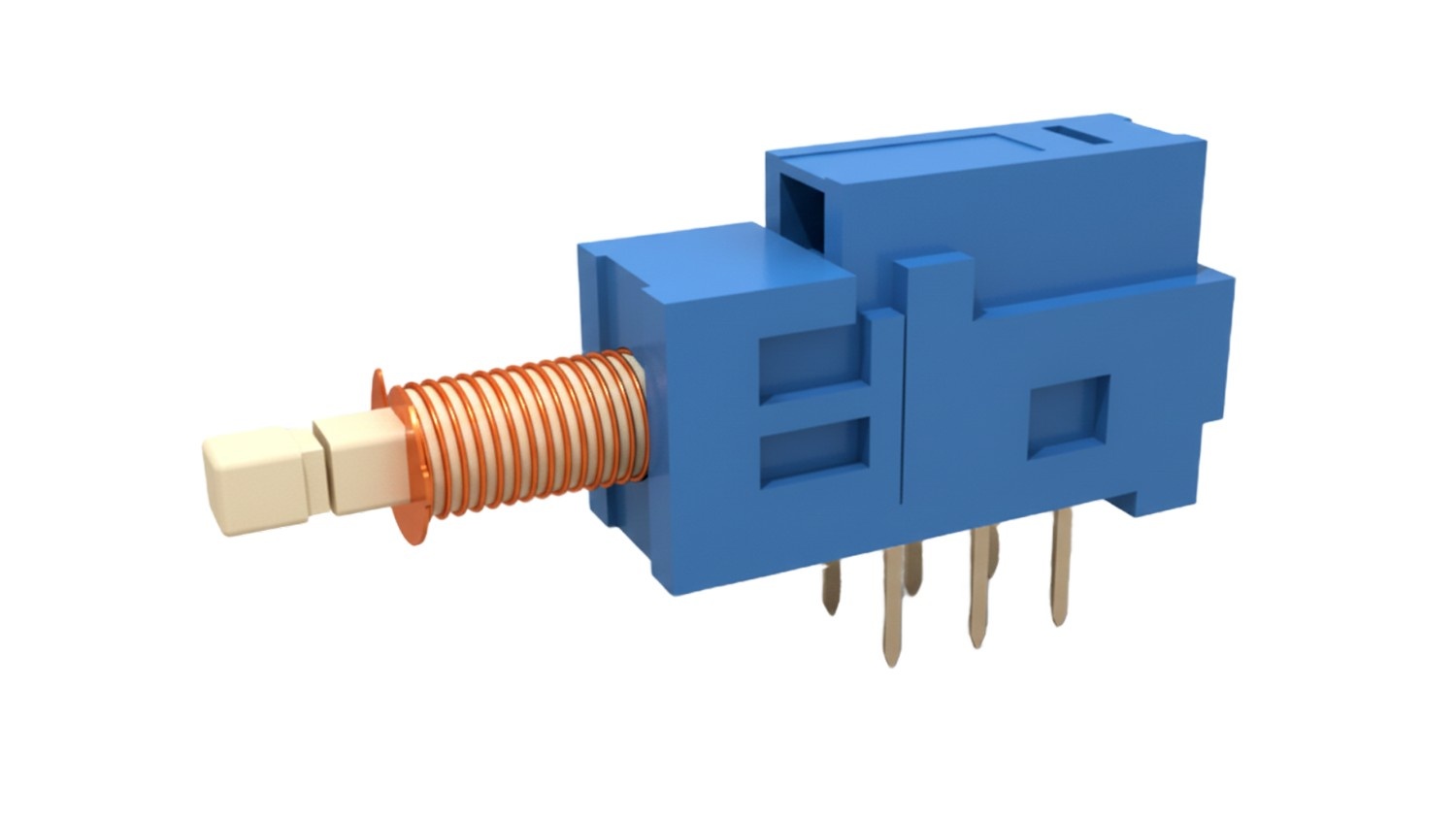

A push-button switch is a simple electrical component used to control the flow of electricity in a circuit by opening or closing it with a mechanical action. When pressed, the actuator (typically a button or knob) engages an internal mechanism that either connects (closes) or disconnects (opens) the circuit.

Working Mechanism of Push-Button Switches

Push-button switches work by physically pressing the actuator, which either opens or closes an internal electrical contact. This action controls the flow of electricity in the circuit, either activating or deactivating connected components.

Actuation: Pressing the button moves the actuator (e.g., a button or knob).

Contact Movement: The actuator engages internal contacts, either closing (connecting) or opening (disconnecting) the circuit.

Momentary Operation: In momentary switches, the circuit remains activated only while the button is pressed.

Maintained Operation: In maintained switches, the button stays in its new position (on/off) until pressed again.

Return Mechanism: Spring-loaded designs typically return the button to its default state after release.

Electrical State: The switch either allows current to flow (closed circuit) or stops it (open circuit), enabling or disabling electrical components.

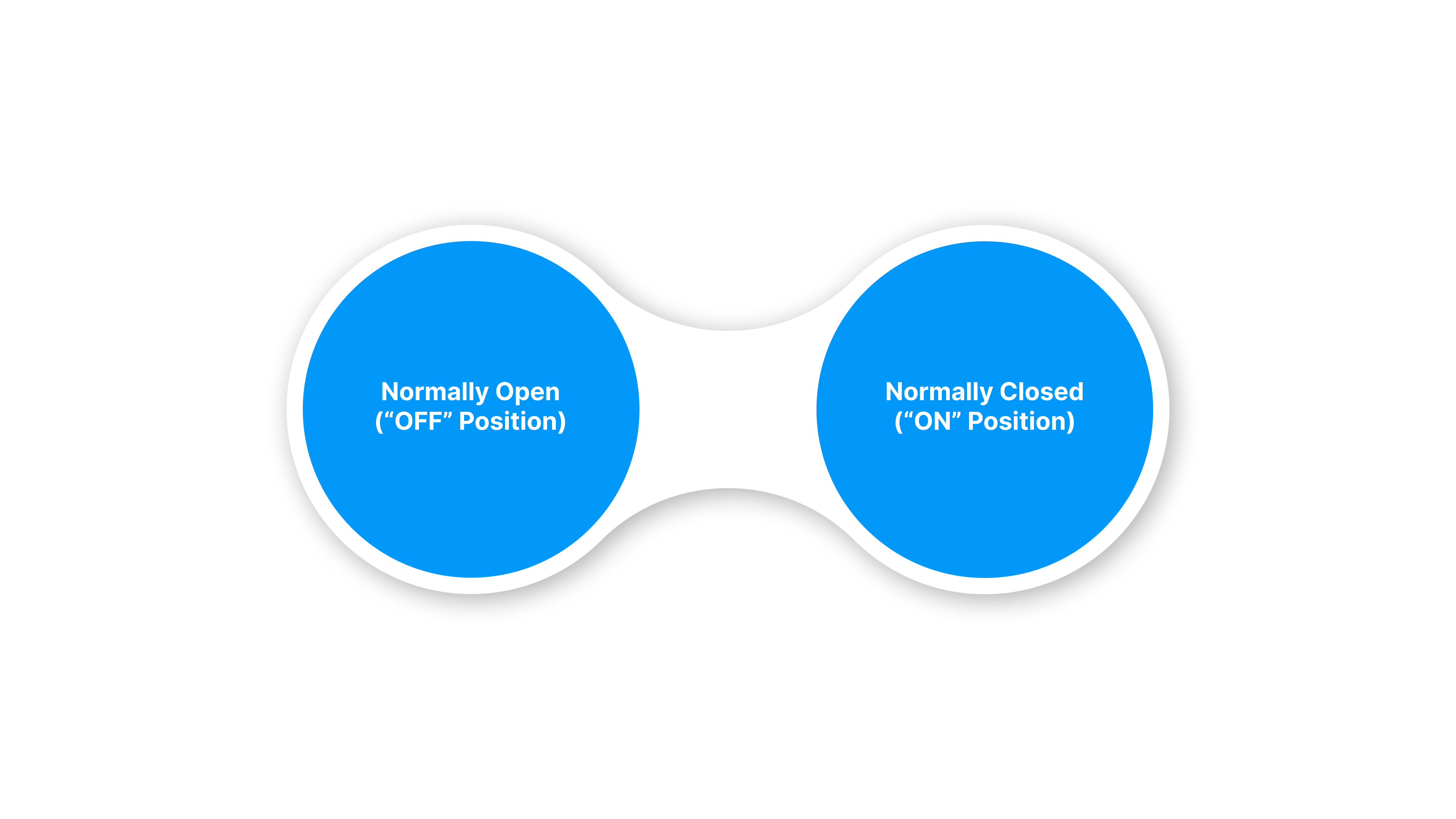

Push‑Button Switch Types: Normally Open vs Normally Closed

Push-button switches are fundamental components in electrical control systems. The simplest way to classify push‑button switches is by their default contact state, normally open (NO) or normally closed (NC). These two types determine the switch's behavior in a circuit when it is not being actively pressed, which has critical implications for how the switch interacts with the rest of the system.

Normally Open (NO) Push-Button Switch

A Normally Open (NO) push-button switch remains open (i.e., no electrical connection) when it is not pressed. This means that the circuit is incomplete, and no current flows. When the user presses the button, the internal contacts close, completing the circuit and allowing electricity to pass through.

Examples:

Start buttons (e.g., turning on a motor or device).

Doorbells (activation when pressed).

Reset buttons (momentary activation).

Normally Closed (NC) Push-Button Switch

In contrast, a Normally Closed (NC) push-button switch has its contacts closed when the button is not pressed, meaning the circuit is complete and current flows. When the button is pressed, the internal contacts open, breaking the circuit and stopping the current from flowing. This behavior is essential in applications where the system must be actively interrupted to stop operation.

Examples:

Emergency stop (E-stop) buttons (shutting down machinery immediately).

Safety interlocks (cutting off power in hazardous situations).

Fail-safe switches (breaking the circuit during faults).

Once you've determined the right contact state for your application, the next decision involves how many circuits you need to control and how many output paths each requires. The pole-and-throw configuration defines these capabilities.

Push Button Switching Circuit Configurations

When you choose a push‑button (or any manual) switch, one of the first decisions is the “pole and throw” configuration. That determines how many circuits the switch handles (poles) and how many outputs each circuit can connect to (throws).

Here’s how the main configurations differ, and what that means when you spec switches for industrial panels, OEM machines, or control systems.

Single Pole, Single Throw (SPST) Switch

A Single Pole, Single Throw (SPST) switch is the simplest type of electrical switch, consisting of a single circuit (pole) and one output path (throw). It works by opening or closing the circuit, allowing or stopping the flow of current. SPST switches are used for basic on/off control.

Benefits of SPST Switches

Easy to use and install due to its straightforward on/off functionality.

Less expensive due to the simple design and fewer components.

Suitable for basic applications like turning lights or equipment on/off.

With fewer moving parts, SPST switches are durable and have a long lifespan.

Small footprint, ideal for compact control panels or devices.

Single Pole, Double Throw (SPDT) Switch

A Single Pole, Double Throw (SPDT) switch controls a single circuit (pole) but provides two output paths (throws). It allows you to switch between two different circuits or states, making it more flexible than an SPST switch. This type of switch is commonly used when you need to select between two options or routes in a circuit.

Benefits of SPDT Switches

Offers two output paths, enabling switching between different circuits or power sources.

Replaces two SPST switches, reducing the need for additional components in a control panel.

Allows toggling between two states or sources, perfect for applications like backup power switching.

Designed for higher reliability and longevity, making it suitable for demanding industrial environments.

Ideal for systems where multiple outputs or sources need to be managed with a single switch.

Double Pole, Single Throw (DPST) Switch

A Double Pole, Single Throw (DPST) switch controls two separate circuits at once, but each circuit only has one output path. When the switch is activated, both circuits are turned on or off simultaneously, making it useful for applications where two circuits need to be controlled together.

Benefits of DPST Switches

Controls two circuits simultaneously with a single switch, reducing wiring complexity and component count.

Ideal for applications where multiple lines need to be disconnected at once, such as power and ground lines.

Replaces two separate SPST switches, saving space and cost in control panels or machinery.

Ensures both circuits are switched together, improving consistency and reducing the chance of faulty operation.

Eliminates the need for two separate switches to control related circuits.

Double Pole, Double Throw (DPDT) Switch

A Double Pole, Double Throw (DPDT) switch is similar to a DPST switch but offers two output paths for each of its two circuits. This means it can switch between two separate outputs for each circuit, giving you greater flexibility in managing multiple devices.

Benefits of DPDT Switches

Can simultaneously manage two circuits, with the ability to toggle between two paths for each circuit.

Ideal for applications requiring complex switching operations, such as reversing motor direction or switching between two power sources.

Replaces two SPDT switches, saving space in control panels and reducing costs.

Provides more advanced control between multiple options in both circuits, such as forward and reverse motor control.

Reduces the number of switches needed in complex systems, making the overall design cleaner and more efficient.

Knowing which configuration you need is only part of the selection process. The specifications determine whether a switch will actually survive in your operating environment and perform reliably over time.

Key Specifications for Push‑Button Switches: What Engineers and Plant Heads Should Check

When specifying push‑button switches for industrial panels, OEM machines, or control systems, the technical details matter. As your technical‑solutions partner, ValuAdd ensures you pick switches that match real-world requirements, not just price. Here are the essential specs to evaluate.

Specification | Selection Criteria |

Voltage and Current Ratings | Ensure the switch is rated for the required voltage and current to prevent failure. |

Contact Configuration (NO/NC) | Defines whether the switch is Normally Open (NO) or Normally Closed (NC), impacting circuit behavior. |

Ingress Protection (IP) | IP rating (e.g, IP65, IP67) for resistance against dust, water, and harsh environments. |

Mechanical & Electrical Endurance | Lifecycle ratings indicate how many actuations the switch can handle before failure. |

Mounting & Physical Form Factor | Choose based on panel cutout size, actuator style (flush, extended), and terminal type. |

Load Type Compatibility | Ensure the switch is rated for resistive or inductive loads, especially for motor control. |

Safety & Compliance Certifications | Look for UL, CE, and IEC certifications for safety-critical applications like emergency stops. |

These specifications matter because push-button switches operate in demanding environments across multiple sectors. Here's where you'll find them doing critical work.

Applications of Push‑Button Switches

In real‑world industrial, commercial, and OEM settings, push‑button switches serve many roles, from simple user interfaces to critical safety controls. Below are key application areas where engineers, plant heads, and OEMs rely on push‑buttons.

Industrial machinery & automation: Push‑buttons are used on machine control panels to start, stop, or reset equipment, or switch between operating modes.

Emergency stop/safety interlocks: In factories, manufacturing plants, and heavy‑duty equipment, NC push‑buttons serve as E‑Stop controls.

Control panels and process control systems: For managing control logic, selecting power sources, toggling between circuits, or activating subsystems.

Consumer and office‑level devices & appliances: Switches in devices such as kitchen appliances, electronic equipment, access panels, and general controls.

Automotive, marine, and specialized vehicles/equipment: For ignition, control circuits, lighting, and safety controls; also for environments demanding rugged, sealed switches (e.g, marine, off‑road, industrial‑grade equipment).

Infrastructure, utilities & heavy‑duty industrial sectors: Plants like power generation, water/wastewater, material processing (metals, cement, chemicals), where robust push‑buttons control motors, conveyors, valves, and safety circuits.

Selecting the right switch for these applications requires more than matching specifications to a datasheet. It takes experience with real-world installations and an understanding of what actually fails in the field.

Why Choose ValuAdd as Your Technical Solutions Partner?

At ValuAdd, we’re not just a product reseller; we are a technical solutions partner based in the Southeastern U.S. Here’s why we’re the right choice for engineers, plant heads, and OEMs:

Local Expertise: Operating in North Carolina, South Carolina, and Virginia, we understand the specific challenges and requirements of these regions, offering tailored solutions for local industries.

Custom Solutions: We assist you in selecting the right combination of products for each unique application, whether it's for OEM machinery, industrial plants, or safety-critical systems.

End-to-End Support: From specifying components to integration and optimization, we make sure that each part of your electrical system functions seamlessly.

Broad Industry Reach: Serving industries like industrial manufacturing, OEM equipment, municipal projects, and commercial facilities, we deliver solutions that meet the diverse needs of our customers.

Conclusion

Push-button switches are essential for the reliable operation of electrical systems across various industries. From basic on/off control to complex safety functions, selecting the right switch type and configuration is crucial to avoid downtime and maintain system reliability.

Understanding the key specifications and applications allows engineers and plant managers to make informed decisions that optimize performance and safety.

At ValuAdd, we help you select the right components for your applications, offering expert guidance and solutions tailored to your needs.

Connect with our industrial electrical experts today to keep your systems running smoothly.

FAQs

What type of switch is a push button?

A push-button switch opens or closes a circuit when pressed. It can be momentary (active only while pressed) or maintained (stays on/off until pressed again).

What are common push-button problems?

Common issues include sticking, faulty wiring, poor contact, and failure to reset, often caused by wear or dirt.

What do L1, L2, L3, and L4 mean on a light switch?

L1, L2, L3, and L4 are live terminals used to connect circuits, allowing control of multiple lights or outlets from a single switch.

What are the disadvantages of push-button switches?

Push-button switches may wear out in high-traffic areas, suffer from contact issues, or fail in harsh environments without proper sealing.

How to check if a push button is working?

Use a multimeter to check for continuity. It should show continuity when pressed (closed circuit) and no continuity when released (open circuit).