Ever had a PLC mysteriously fail, an HMI go black, or a VFD trip for “no reason”? No storm. No blackout. Just unexpected downtime and frustrated technicians.

Chances are, the culprit wasn’t a power outage; it was a surge. These microsecond voltage spikes are often invisible yet incredibly destructive to sensitive automation hardware.

Industrial facilities experience over 150 power surges per month, and 60–80% of them originate inside the plant from motors, VFDs, switching, and heavy equipment.

For plants relying on PLCs, sensors, SCADA, robotics, and modern controls, even tiny surges can trigger thousands of dollars in downtime, equipment damage, and troubleshooting chaos.

This guide explains how surge protectors (SPDs) work, why industrial environments face higher surge threats, the technology behind MOVs, GDTs, and filtering, and how a layered approach keeps equipment protected and operations stable.

Let’s break it down,

Key Highlights

Surges are the silent killers of industrial electronics; plants face 150+ power surges per month, most created inside the facility by motors, VFDs, and switching events.

Even microsecond spikes can reset PLCs, trip VFDs, burn sensors, corrupt logic, and black out HMIs, causing thousands in downtime without leaving obvious evidence.

Surge Protection Devices (SPDs) work by instantly clamping and diverting excess voltage, keeping automation hardware safe while maintaining continuous operation.

No single SPD can handle every type of surge, so plants need a layered approach: service entrance + distribution panel + equipment-level protection.

ValueAdd helps facilities deploy engineered surge-protection and clean-power solutions, preventing hidden electrical stress and improving long-term equipment reliability.

What Is a Surge?

A surge, also called a transient overvoltage, is a sudden, short-duration spike in electrical voltage that temporarily exceeds the normal operating level of an electrical system.

Surges typically last microseconds to milliseconds, but generate energy high enough to damage or prematurely degrade electronic components, especially sensitive automation hardware like PLCs, HMIs, sensors, and VFD control boards.

In a standard industrial low-voltage system (120–480VAC), even a brief rise of several hundred volts above nominal can exceed insulation ratings or semiconductor tolerances, leading to failures ranging from nuisance resets to catastrophic electronics burnout.

Why Surges Occur in Industrial Environments?

Industrial facilities experience surges more frequently than most electrical environments due to the nature of their equipment and power-system dynamics. Key contributors include:

1. Heavy Inductive Loads & Motor Switching

Large motors, pumps, compressors, and industrial machinery create inductive kickback when started or shut down, releasing stored magnetic energy back into the power system.

2. VFDs, Soft Starters & Power Electronics

Variable Frequency Drives, servo drives, soft starters, UPS systems, welders, and rectifiers rapidly switch power electronically.

3. Utility Grid Switching & Power Instability

Events such as capacitor bank switching, transformer tap changes, fault clearing, and utility service restoration can cause plant-wide voltage spikes.

4. Lightning (Direct & Indirect)

Lightning does not need to strike a facility directly to cause damage; nearby strikes induce voltage spikes through overhead lines, buried cables, and building structures.

5. Harmonics & Noise Interaction

Modern plants rely heavily on drives and digital power systems that distort sinusoidal waveforms, creating harmonics. These distortions interact unpredictably with switching events, amplifying transient effects.

6. Long Cable Lengths & Distributed Systems

Extended conduit runs to field devices increase impedance, which magnifies surge voltage peaks. Distributed control architectures (remote I/O, field instrumentation, networks) are particularly vulnerable.

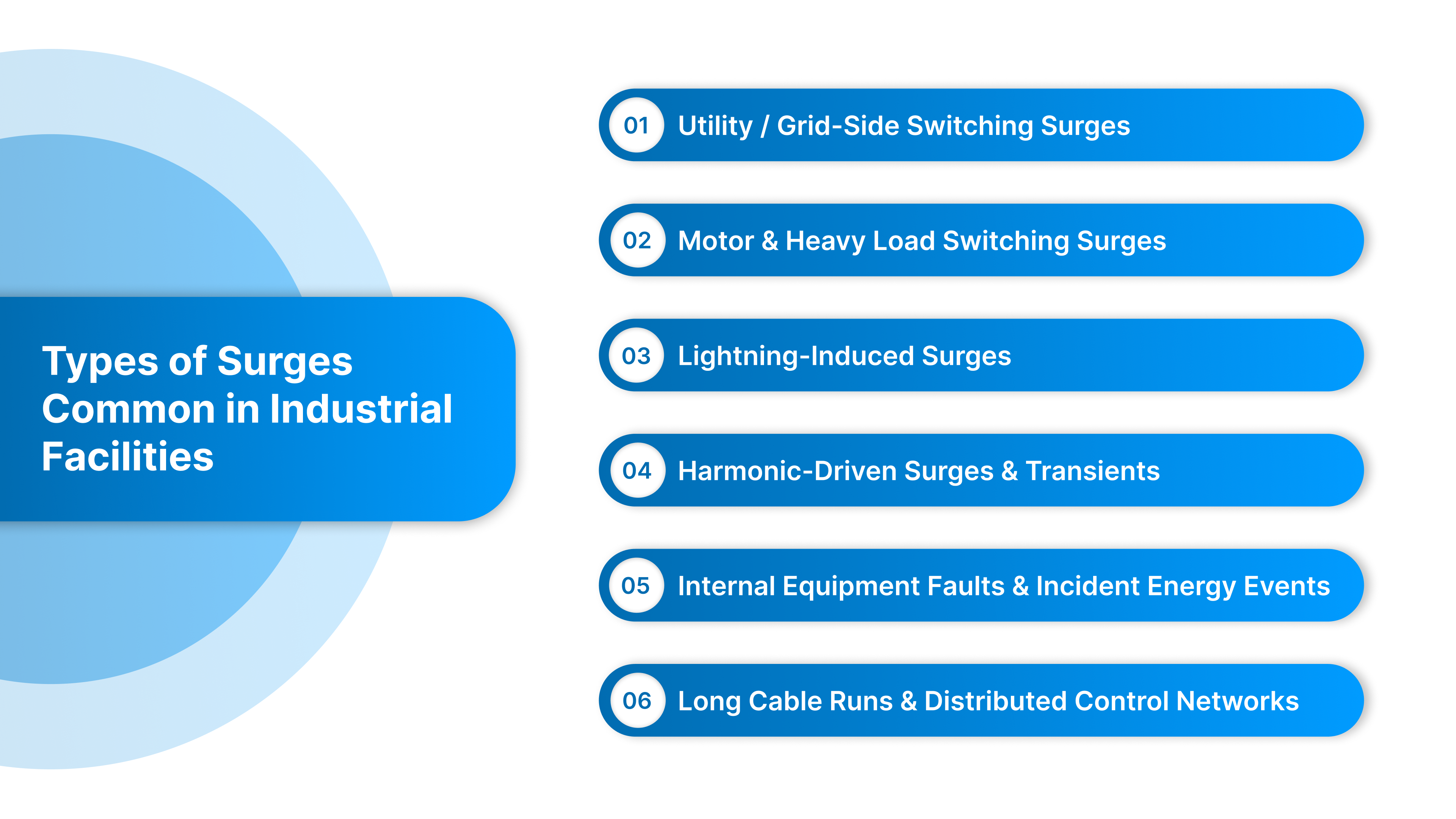

Types of Surges Common in Industrial Facilities

Industrial power systems experience several different types of surges, each with distinct causes, characteristics, and impacts on equipment performance and lifespan. Understanding these categories helps determine proper surge-protection placement and device selection.

A. Utility / Grid-Side Switching Surges

These surges originate from the electrical utility or external distribution network. Events such as capacitor bank switching, transformer tap changes, feeder transfers, and power restoration after outages generate high-energy transients. Because they enter at the service entrance, they can propagate through the entire plant and affect multiple systems simultaneously.

Typical Symptoms

Multiple systems failing or rebooting at once

Widespread VFD trips or HMI resets

Unexplained faults after utility switching events

Primary Protection Strategy: High-capacity SPDs at service entrance and main distribution panels

B. Motor & Heavy Load Switching Surges

Large inductive equipment, including motors, pumps, compressors, conveyors, hydraulic power units, and magnetic devices, produces surges when they switch on/off. Stored magnetic energy collapses and produces voltage spikes that travel backward onto the power lines.

Resulting Problems

PLC input module failures

Network communication drops

Motor drive and control board damage

Surge Source: Occurs inside the facility and is typically repetitive, accelerating electronic aging.

C. Lightning-Induced Surges

Lightning strikes (direct or nearby) induce extremely high-energy transients through:

Overhead power lines

Long underground cable runs

Ethernet or signal cabling

Building structural grounding paths

Even indirect lightning can introduce thousands of volts in microseconds, enough to instantly destroy sensitive electronics.

High-risk environments

Outdoor pump stations

Water/wastewater facilities

Industrial campuses with multiple buildings

Remote OEM systems or skid-mounted equipment

D. Harmonic-Driven Surges & Transients

Modern facilities use abundant variable speed drives, soft starters, welders, UPS systems, and switching power supplies, which distort the electrical sine wave and create harmonics. These distortions interact with switching events, causing transient spikes and instability.

Common Effects

VFD nuisance trips

Process instability based on sensor noise

Premature failure of power-supply components

E. Internal Equipment Faults & Incident Energy Events

Arcing faults, panel failure, switchgear operation, or UPS transfer switching can induce sharp transient spikes with high destructive potential.

F. Long Cable Runs & Distributed Control Networks

Facilities with remote equipment or long control wiring runs naturally increase surge impact due to:

Increased impedance

Higher voltage peaks at line ends

Increased exposure to induced lightning energy

Examples

Remote I/O cabinets

Field transmitters and instrumentation

Crane and conveyor runway power systems

Each surge source behaves differently, meaning no single device or location provides total protection.

How Surge Protection Devices (SPDs) Work

A Surge Protection Device (SPD) is designed to prevent transient overvoltage events from damaging sensitive electrical and electronic equipment. SPDs operate using non-linear components that behave differently depending on system voltage conditions:

Under normal voltage, the SPD remains in a high-impedance (non-conducting) state, effectively invisible to the electrical system and allowing power to flow normally.

When a surge occurs, and the voltage exceeds a predetermined clamping threshold, the SPD instantly transitions to a low-impedance (conducting) state, providing a safe path for excess energy to bypass downstream equipment.

Once the surge has passed, the SPD returns automatically to its high-impedance state, resuming normal operation.

This rapid switching response (measured in nanoseconds to microseconds) protects equipment like PLCs, HMIs, sensors, VFDs, and communication hardware that cannot withstand sudden voltage spikes.

How SPDs Prevent Damage

During a surge event, the SPD diverts or absorbs transient energy and limits the voltage delivered to downstream devices. Instead of the surge traveling into control electronics and causing damage, it is safely directed to the grounding system or neutral, depending on SPD type and installation location.

Key Outcomes

Peak surge voltage is reduced to a safe level.

Sensitive loads remain protected while power continuity is maintained.

Catastrophic failures and nuisance trips are avoided.

Electronic lifespan and system reliability are significantly extended.

SPD Protection Mechanisms

SPDs use several mechanisms to manage transient energy. Depending on technology and design, an SPD may use one or multiple approaches:

Protection Approach | Description | Typical Use Cases |

Clamping | The SPD activates when the voltage exceeds the rated threshold and clamps the voltage to a safe level | MOV-based devices in AC power distribution |

Shunting / Diversion | Surge energy is redirected through a low-resistance path to ground or neutral | GDT arresters, hybrid multi-stage systems |

Filtering / Conditioning | Removes or smooths high-frequency electrical noise and harmonics | Protecting PLC I/O, instrumentation circuits, and communication lines |

SPDs provide electronic response times thousands of times faster, making them essential for protecting modern automation infrastructure.

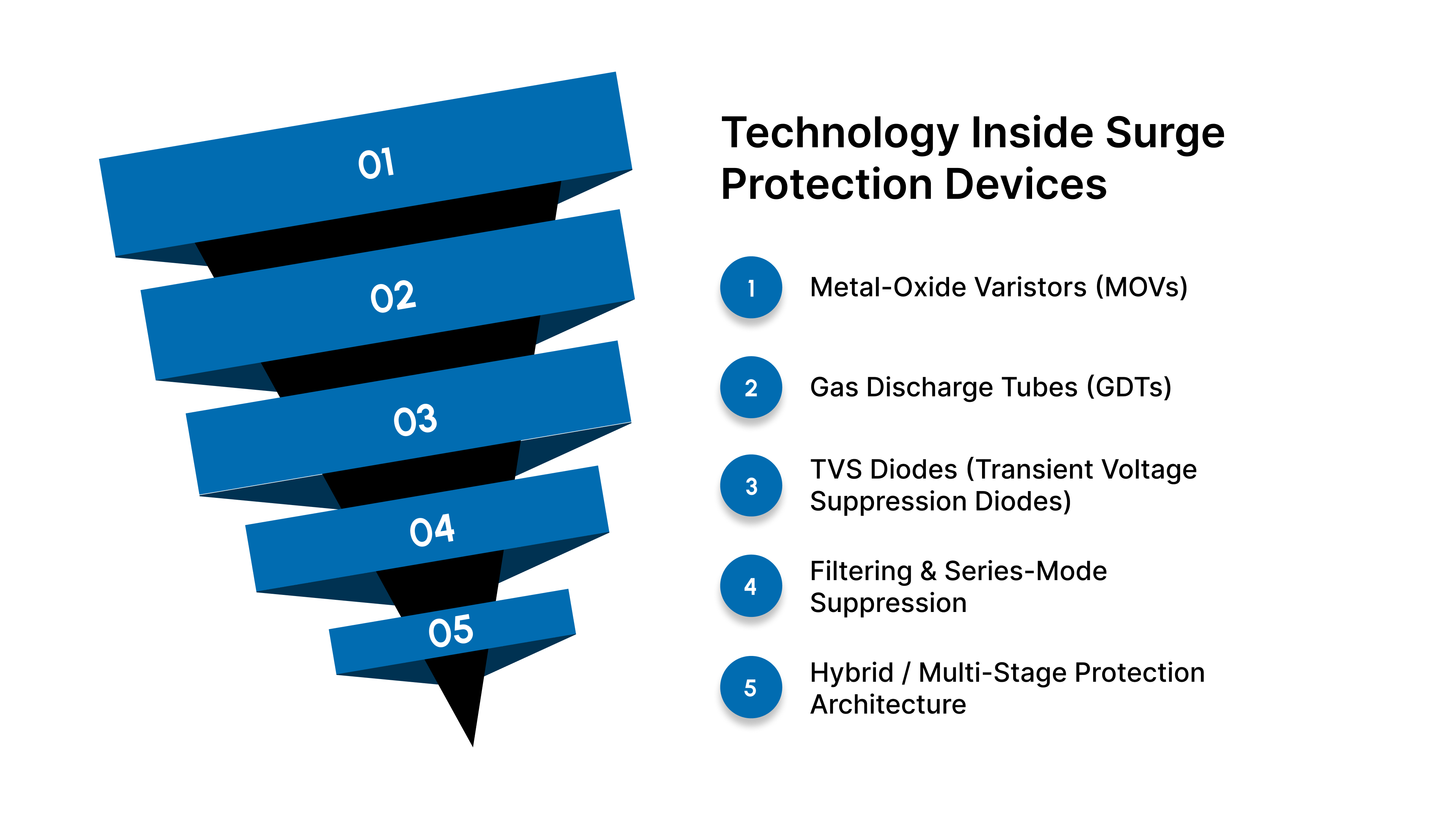

Technology Inside Surge Protection Devices (SPDs)

Modern SPDs use advanced component technologies, individually or in combination, to safely manage surge energy, maximize response speed, and extend equipment life in industrial environments.

A. Metal-Oxide Varistors (MOVs)

MOVs are one of the most common surge-protection elements used in AC and DC power applications.

How MOVs Work (Electrically)

Constructed from zinc oxide (ZnO) grains sandwiched between metal electrodes.

Behave according to a nonlinear V-I (voltage-current) characteristic, meaning:

At normal operating voltage (e.g., 480V RMS), the MOV’s resistance may range from megaohms to hundreds of kilo-ohms, effectively open-circuit.

When surge voltage exceeds the clamping threshold (e.g., 775–1200V let-through for a 480V MOV), resistance collapses to below 1 ohm, allowing large surge currents to be diverted.

Strengths

Extremely fast response time.

Effective for repetitive smaller transients and switching surges.

Well-suited for panel-level and facility-level protection.

B. Gas Discharge Tubes (GDTs)

GDTs are designed for high-energy surge diversion and long-life transient protection.

How They Work

A sealed chamber filled with inert gas between two electrodes.

When voltage exceeds the sparkover threshold (e.g., 600V–3500V depending on type), the gas ionizes and becomes plasma.

After the event, the gas de-ionizes and returns to an insulating state.

Strengths

Handles very large surge currents and lightning-class impulses.

Low capacitance, ideal for instrumentation, data, and telecom circuits.

Long lifespan and excellent endurance.

C. TVS Diodes (Transient Voltage Suppression Diodes)

TVS diodes are semiconductor-based surge protectors engineered for rapid response.

How They Work

Clamp voltage instantly when the threshold is exceeded.

Designed to absorb short-duration high-energy pulses.

Strengths

Fastest response time of any surge component (picoseconds to nanoseconds).

Precise protection for sensitive signals and low-voltage electronics.

D. Filtering & Series-Mode Suppression

Filtering systems use inductors, resistors, and capacitors to smooth high-frequency noise and repetitive transient disturbances.

Benefits

Stabilizes process signals and reduces VFD-induced electrical noise.

Prevents nuisance trips on sensitive equipment.

Ideal complement to clamping or shunting protection.

E. Hybrid / Multi-Stage Protection Architecture

The most effective industrial surge-protection systems combine multiple protective technologies to address different surge characteristics.

Example Multi-Stage SPD Design

Stage | Technology | Role in Protection System |

1 | GDT | Handles large surge spikes (e.g., lightning) |

2 | MOV | Clamps the transient voltage to safe levels |

3 | TVS / Filtering | Protects sensitive electronics and signal integrity |

Because no single technology can handle every surge effectively, facilities rely on layered SPDs for complete protection.

This multi-stage approach delivers stronger energy absorption and faster response, ideal for automation-heavy systems, VFDs, long cable runs, and remote I/O environments.

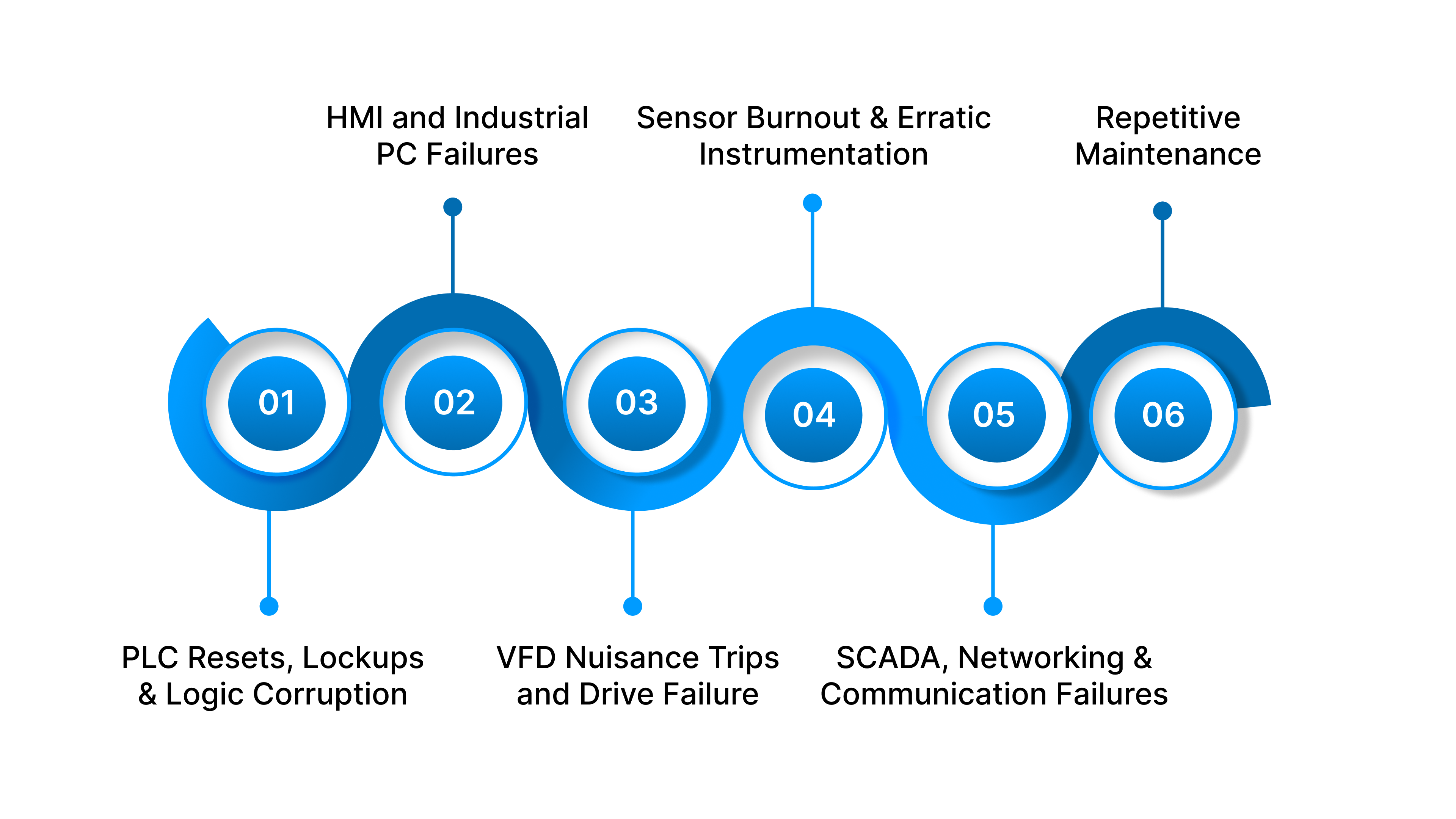

Common Industrial Pain Points Solved by Surge Protection

Surge protection is not just about preventing catastrophic equipment failure; it also eliminates recurring operational problems that destroy productivity, reliability, and maintenance efficiency.

1. PLC Resets, Lockups & Logic Corruption

Transient voltage spikes can disrupt microprocessor timing and memory integrity inside PLCs, even if the surge does not destroy hardware.

Random PLC reboot during production

Intermittent I/O faults without an identifiable root cause

Control sequence errors requiring manual reset

Clean, stable voltage to power supplies and I/O backplanes prevents logic disruption and ensures uninterrupted operation.

2. HMI and Industrial PC Failures

HMIs and industrial PCs use sensitive display drivers and power supply components that are easily stressed by voltage spikes.

Black screens or frozen interfaces

Touch panel calibration failure

Display or communication port failure

Prevent voltage spikes that degrade internal electronics and extend display life cycles, reducing emergency replacement needs and long lead time delays.

3. VFD Nuisance Trips and Drive Failure

Drives are both generators and victims of electrical noise. Surges can trigger:

Overvoltage or undervoltage trips

Fault codes without a consistent root cause

Premature failure of input rectifiers and DC bus capacitors

Cost Impact: A single 30-minute VFD-driven process stoppage can cost thousands of dollars in downtime, plus maintenance labor.

Isolation and filtering stabilize drive performance and prevent feedback surges from damaging upstream circuits.

4. Sensor Burnout & Erratic Instrumentation

Long cable runs to field devices act as antennas for transient energy.

False readings and analog signal drift

Blown 4–20mA transmitters

Loss of the fieldbus or network nodes

SPD and filtering at field junction boxes or distributed I/O cabinets protect low-level signals and maintain reliable data.

5. SCADA, Networking & Communication Failures

Even minor surges cause packet loss, ground loops, and port failures.

Random disconnects

Device “not responding.”

Cycling Ethernet/serial card replacements

TVS-based and RJ45 surge protection maintain communication integrity and reduce troubleshooting man-hours.

6. Repetitive Maintenance & Hard-to-Find Ghost Faults

Many plants face unexplained downtime where technicians replace parts without ever identifying the real cause (surge-driven degradation).

Higher spare-parts usage

Weekend call-outs and overtime labor

Degraded reliability reputation with operations

Remove the hidden cause behind intermittent problems, returning predictable reliability to production systems.

How Valuadd Strengthens Surge Protection & Power Reliability

Valuadd supports industrial facilities, OEMs, panel shops, and utilities across North Carolina, South Carolina, and Virginia with engineered surge-protection and power-quality solutions that protect automation systems, prevent downtime, and improve overall electrical reliability.

Provides industrial Surge Protection Devices (SPDs) and low-voltage protection components from manufacturers such as NOARK Electric to protect PLCs, VFDs, HMIs, SCADA, I/O systems, sensors, and networking equipment from transient spikes, switching surges, lightning pulses, and harmonics-related disturbances.

Delivers clean backup power and ride-through capability using Marathon Power UPS systems, maintaining stable power for critical controls, remote I/O, instrumentation, communication hardware, and SCADA when voltage dips, flickers, or outages occur.

Supports engineering teams with expert application guidance to correctly select and apply surge protection at the service-entrance, distribution, and point-of-use levels, ensuring true layered protection and eliminating costly nuisance downtime.

Enables OEMs and panel shops to standardize designs using coordinated industrial-grade components such as Macromatic monitoring and protection relays, improving reliability across recurring builds and preventing failures due to phase loss, voltage imbalance, overload, or cycling shock.

Supplies industrial control components and panel hardware from lines such as Finder relays, BACO pilot devices, and TCI power-quality/reactive filtering solutions, supporting stable and noise-free control architectures.

ValuAdd gives you a fully engineered protection system, not a patchwork, shielding you from both major surges and silent electrical stress.

Application Engineering Examples

Real-world ways surge protection, UPS power stability, and monitoring improve reliability in industrial environments and OEM systems.

Installing an SPD at the main incoming distribution panel in a plant or facility to stop high-energy transients from entering the electrical system and damaging downstream automation equipment.

Adding a secondary SPD at VFD and motor-control panels to prevent drive trips, DC-bus failures, and feedback surges from affecting upstream power circuits or other connected equipment.

Protecting critical automation loads such as PLCs, HMIs, remote I/O, SCADA servers, and networking hardware with UPS systems to maintain stable clean power during voltage dips, sags, brownouts, and momentary outages.

Using monitoring and protection relays to log abnormal electrical events, detect phase imbalance or undervoltage, and provide alarms or data for preventive maintenance planning.

Integrating surge protection and power conditioning at the OEM machine design stage to increase field reliability, reduce warranty service calls, and strengthen customer confidence in delivered equipment.

Applying layered facility-level protection architectures from service entrance → distribution panels → equipment-level SPDs for complete system coverage and reduced exposure to localized transients.

Conclusion

Reliable surge protection and power-quality planning are no longer optional in modern industrial environments; they are essential for uptime, equipment longevity, and consistent automation performance. By applying layered surge protection, clean-power solutions, and engineered placement strategies, facilities can eliminate unexpected failures, protect high-value assets, and operate with confidence.

Suppose you’re building new control systems, upgrading existing panels, or facing recurring unexplained downtime. In that case, valuadd can help you evaluate risks, select the right surge-protection and power-quality approach, and apply it correctly across your facility or OEM equipment.

Contact valuadd for application support, SPD selection guidance, and engineered power-protection strategies across NC, SC, and VA.

Frequently Asked Questions (FAQ)

1. What causes electrical surges in industrial facilities?

Surges are typically caused by motor switching, VFD activity, soft starters, compressors, welding equipment, utility grid fluctuations, and lightning (direct and induced). Long cable runs and harmonics also increase exposure to transient spikes.

2. How long do SPDs last, and when should they be replaced?

SPD lifespan depends on surge exposure and design. Each surge event slightly degrades the protection components. Devices should include status indication or monitoring relays to track health and replacement timing.

3. Where should Surge Protection Devices (SPDs) be installed in an industrial plant?

The most reliable strategy uses layered protection: service entrance → distribution panels → equipment-level SPDs on control panels, MCCs, and OEM machines.

4. Do SPDs protect against every type of electrical disturbance?

SPDs protect against transient voltage spikes, but UPS systems and filtering are needed to handle dips, sags, brownouts, and electrical noise. A full solution often requires both.

5. How do I know if my facility needs surge protection upgrades?

Common warning signs include unexplained PLC resets, VFD nuisance trips, burnt sensors, HMI screen failures, intermittent communication issues, or frequent replacement of components without a clear cause.