What if the biggest threat to your production line isn’t a power outage, but a barely noticeable voltage dip that lasts only a few seconds? Unlike outages or surges, it often slips under the radar until motors begin to stall, drives trip unexpectedly, PLCs reset, or production grinds to a halt.

Even minor drops in voltage can trigger performance issues, accelerate wear on sensitive components, and lead to unpredictable maintenance challenges.

Over time, these hidden disturbances turn into costly problems: unplanned downtime, reduced process reliability, premature equipment failure, and hours spent troubleshooting issues that seem to appear out of nowhere.

This guide is tailored for plant engineers, controls engineers, OEM project managers, panel shops, system integrators, and electrical distributors, anyone responsible for keeping production running smoothly.

Key Takeaways

Undervoltage is a hidden reliability threat, causing intermittent faults, stalled motors, PLC resets, and costly downtime long before failures are obvious.

Even minor voltage drops accelerate equipment wear, leading to overheated motors, repeated VFD faults, and shortened lifespan of control electronics.

Protection requires a multi-layer strategy, combining engineering design (right conductor sizing, staged motor starts, clean power) with devices like monitoring relays, UPS systems, and line reactors.

Targeting the most sensitive loads first, PLCs, HMIs, VFD-heavy lines, and critical panels, reduces nuisance trips, improves uptime, and prevents unnecessary component replacements.

Partnering with technical experts like ValuAdd ensures correct application engineering, standardized BOMs, and locally supported solutions that boost reliability and reduce downtime.

What Is Undervoltage?

Undervoltage is a sustained reduction in electrical supply voltage below the acceptable operating tolerance for equipment, typically defined as more than 10% below nominal voltage for a duration long enough to affect performance. Unlike a momentary fluctuation, undervoltage persists and degrades equipment operation over time.

How Undervoltage Differs From Other Power Disturbances

Not all low-voltage events are the same. Differentiating disturbances helps determine the correct protection approach.

Voltage Sag: A short, momentary drop in voltage lasting milliseconds to a few seconds, often caused by motor inrush or switching.

Power Outage: A complete loss of power, typically caused by faults or service interruption.

Where Undervoltage Commonly Occurs

Undervoltage can appear at multiple points inside an industrial facility, affecting everything from heavy equipment to sensitive control electronics.

Service entrance & main switchgear

Distribution panels and MCCs (Motor Control Centers)

Local control panels and OEM equipment skids

Automation electronics: PLCs, HMIs, industrial PCs, and 24VDC control systems

Symptoms & Real-World Operational Impact

Undervoltage rarely presents itself with a single obvious fault. Instead, it creates a trail of confusing, intermittent issues that waste time, cause finger-pointing, and drive up maintenance costs. The key to solving undervoltage is recognizing the subtle warning signs before they escalate into major downtime events.

Common Visible Symptoms

These are the practical, plant-floor indicators that undervoltage is affecting equipment performance, even when meters show “acceptable” voltage.

Motors running hotter than normal, losing torque, or stalling under load: When voltage drops, motors draw more current to maintain torque, which overheats windings and accelerates insulation breakdown. This leads to nuisance overload trips, reduced efficiency, and shortened equipment life.

Variable Frequency Drives (VFDs) are faulting unexpectedly or resetting during acceleration: Drives require a stable voltage to maintain DC bus levels. Undervoltage causes bus collapse, triggering undervoltage faults, derating behavior, or unexplained resets that halt production lines.

PLCs, HMIs, and control electronics intermittently locking up or resetting: Even small drops in control power cause sensitive logic components to reboot or lose communication. Because faults clear when the voltage recovers, troubleshooting becomes time-consuming and frustrating.

Lighting dimming or flickering during equipment starts or load shifts: A classic indicator of voltage drop caused by inrush current, overloaded circuits, or insufficient distribution capacity.

Business & Safety Consequences

The operational impact extends far beyond a single fault; undervoltage threatens productivity, equipment longevity, and plant safety.

Unplanned downtime and lost production throughput: A single nuisance trip on a drive or PLC can stop an entire line, costing thousands of dollars per hour, depending on the industry.

Premature failure of motors, drives, transformers, contactors, and control electronics: Excess heating and repeated resets significantly shorten asset lifespan and increase capital replacement frequency.

Increased maintenance labor and emergency troubleshooting: Intermittent symptoms often lead teams to replace good components, wasting time and resources without fixing the real cause.

Quality deviations and safety risks due to unstable processes: In batch or continuous processing environments, a momentary equipment reset can cause contamination, scrap, improper sequencing, or unsafe conditions.

Undervoltage is not just a power quality problem; it is a reliability and profitability problem. Facilities that proactively monitor and protect against undervoltage experience fewer failures, longer equipment life, and more predictable operations.

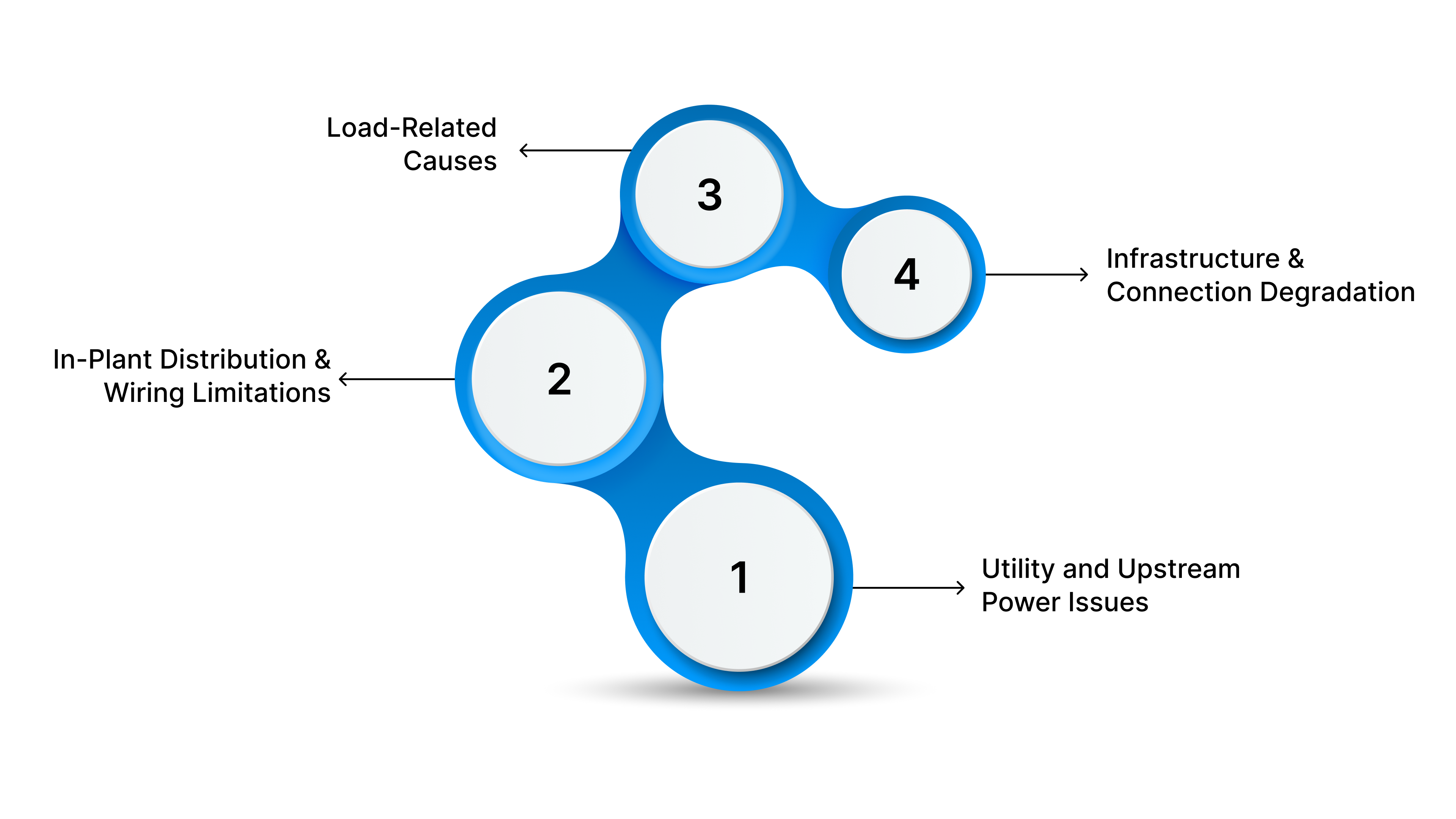

4 Common Causes of Undervoltage

In many cases, the root cause is not a single failure, but the cumulative effect of load growth, aging equipment, and poor power distribution practices. Understanding these sources is essential for diagnosing and preventing recurring issues.

1. Utility and Upstream Power Issues

External power problems are often blamed first, but they are only part of the picture.

Utility brownouts and peak-demand loading: During high-demand periods, utilities intentionally reduce voltage to stabilize the grid, causing widespread undervoltage in industrial areas.

Long feeder distances or remote locations: Facilities far from substations experience natural voltage drop across long conductors, especially when loads increase.

Weather, infrastructure wear, and upstream switching: Storms, equipment aging, and switching operations can reduce delivered voltage even without a visible outage.

2. In-Plant Distribution & Wiring Limitations

Most undervoltage issues originate internally due to distribution bottlenecks, poor design, or equipment growth over time.

Undersized conductors or long cable runs: Voltage drop increases with distance, current load, and conductor resistance, turning remote equipment into weak points during startup.

Overloaded distribution panels or transformers: As plants expand, additional loads are often added without re-evaluating capacity, creating persistent low-voltage zones.

Improperly tapped or aging transformers: Incorrect tap settings or degraded windings reduce secondary voltage stability.

3. Load-Related Causes

Sudden, heavy loads can cause instantaneous dips that trigger undervoltage symptoms across surrounding circuits.

Large motors starting across the line (high inrush): Motors may draw 6–8x full-load amperage at startup, causing localized voltage drops that ripple through the system.

Clusters of VFDs and nonlinear loads concentrated on the same bus: Heavy drive usage introduces harmonics and distortion, weakening voltage stability and stressing nearby electronics.

Simultaneous startup of multiple machines or compressors: Poor coordination amplifies voltage drop and increases nuisance tripping.

4. Infrastructure & Connection Degradation

Mechanical and environmental issues can create hidden resistive losses that mimic or worsen undervoltage conditions.

Loose, corroded, or damaged terminals and lugs

Heat-stressed MCC buckets or breaker contacts

Aging cables with increased resistance

These faults often do not appear in normal inspections, yet they create voltage drop hotspots that become intermittent downtime drivers.

A single failure point rarely causes undervoltage; it is typically the downstream effect of incremental electrical weakness building up over time.

How Undervoltage Damages Industrial Equipment?

Undervoltage affects electrical and automation systems differently, and its impact often grows silently over time. Some effects are immediate, like nuisance trips, while others quietly degrade equipment until unexpected failure occurs.

The table below summarizes how undervoltage harms key industrial assets.

Asset / Equipment Type | Impact of Undervoltage |

Motors | Overheating, increased current draw, reduced torque, insulation damage, and significantly shortened lifespan |

VFDs (Variable Frequency Drives) | DC bus collapse, nuisance undervoltage faults, unexpected resets, derating under load, unstable drive performance |

PLCs / HMIs / Industrial PCs / Control Electronics | Random resets or lockups, corrupted or lost process data, intermittent I/O failures, and communication drops |

MCCs / Breakers / Contactors / Relays | Nuisance tripping, coil dropout, premature wear, arcing, or failure to latch, loss of protection coordination |

Critical Processes & Safety Systems | Sudden system shutdowns, unsafe operating states, batch contamination or scrap, instability across production lines |

How to Protect Industrial Equipment From Undervoltage?

Effective undervoltage protection requires both smart electrical system design and the right protective devices. The goal is not only to detect undervoltage conditions but also to prevent equipment damage, improve system stability, and maintain reliable plant operation.

1. Engineering & Design Strategies

These proactive measures strengthen the electrical system and reduce the likelihood of undervoltage events causing operational issues.

Use correct conductor sizing & optimized distribution topology

Oversized wire and strategic distribution layouts reduce voltage drop across long feeder runs and remote equipment loads.Sequence and manage motor starting to limit inrush-related voltage drop

Soft starters or staged starts prevent large motors from collapsing the system voltage during acceleration.Reduce distortion with line reactors & harmonic filters

Conditioning VFD-heavy systems improves voltage stability, protects drives, and reduces nuisance faults.Separate sensitive automation loads from power circuits

Isolating PLCs, HMIs, and industrial PCs from motor feeders prevents resets and communication failures.Improve 24VDC reliability with buffered or redundant power supplies

Even small dips in control power can disrupt automation, and buffering helps maintain stability.Verify breaker undervoltage trip settings & coordination

Proper protection settings prevent nuisance trips and maintain selective protection across downstream loads.Maintain appropriate enclosure cooling and environment control

Heat increases sensitivity to undervoltage and accelerates electronic aging; thermal management protects reliability.

2. Protection & Power Quality Equipment

Pairing engineering best practices with the right equipment provides a layered defense, detecting undervoltage early, maintaining operation when needed, and protecting assets from damage.

Protection Need | Solution Type | Relevant Product Categories |

Detect undervoltage and trip before equipment damage occurs | Monitoring Relays | Macromatic, Finder |

Stabilize voltage, reduce harmonics & prevent drive faults | Power Quality (Line Reactors & Harmonic Filters) | TCI |

Maintain automation and control logic during disturbances | UPS Systems | Marathon Power |

Protect circuits, maintain safety & ensure reliable disconnect | Breakers, Switches, Transfer Switches | |

Protect electronics from heat and environmental stress | Industrial Enclosures & Climate Control | Saginaw, Fibox |

Choosing the Right Protection Equipment

Effective undervoltage protection begins with a clear understanding of the application, the critical loads involved, and the operational priorities of the facility.

Key Application Questions

These questions help determine whether the priority is monitoring, protection, or maintaining uninterrupted process performance.

Which equipment is most sensitive to voltage drops?

(Motors vs. VFDs vs. PLC/HMI systems vs. instrumentation)Where in the power path is the voltage drop occurring?

(Service entrance, MCC, distribution panel, local panel, device level)Is the goal early warning, automatic shutdown, or continuous operation?

What level of downtime risk is acceptable for this process or asset?

Is control power already buffered or redundant?

Asking these questions early prevents overspending in low-risk areas and under-protecting critical systems.

Recommended Configuration Examples

Practical pairing strategies based on real-world application needs.

Critical automation and control panels

UPS + monitoring relay + quality enclosure cooling

Ensures PLC/IPC systems remain stable and protected during dips.VFD-intensive production lines

Line reactors or harmonic filters + monitoring relays

Reduces drive trips, improves DC bus stability, and extends drive life.Motor-heavy systems with high inrush loads

Soft start sequencing + properly sized conductors + selective protection

Prevents system-wide voltage collapse and nuisance overload trips.Facility-wide reliability strategy

Power monitoring + protection coordination + power quality review

Creates long-term operational stability and maintenance predictability.

Working With Techni-Reps & Local Electrical Distribution in NC, SC, or VA

Successful implementation requires both technical expertise and product availability across North Carolina, South Carolina, or Virginia.

Collaboration with engineers, OEMs, panel shops & system integrators on application design.

Support for BOM standardization to reduce complexity and improve repeatability.

Joint field calls, training, and product demonstrations with distributor partners.

Regional stock availability and support planning to reduce lead-time risk.

Choosing undervoltage protection is about building a reliable electrical ecosystem, not simply adding devices.

How ValuAdd Supports Reliable Undervoltage Protection & System Performance?

Protecting industrial equipment from undervoltage requires more than just selecting components. Successful outcomes depend on proper application engineering, coordination with electrical distribution, and access to manufacturers with proven solutions.

ValuAdd acts as a technical partner, helping OEMs, industrial facilities, panel shops, and distributors build reliable, standardized power and control systems.

Application Expertise & Engineering Support

ValuAdd goes beyond traditional sales support. It acts as a field-based solution partner focused on solving real-world electrical challenges.

Collaborative support for plant engineers, controls engineers, and OEM project teams.

Guidance on specifying undervoltage protection, power quality solutions, and control panel design.

Recommendations aligned with UL, NEC, and industrial best-practice requirements.

Review of single-line diagrams, panel layouts, and load lists to identify weak points and improvement opportunities.

Standardization & Design Optimization for OEMs and Panel Shops

Standardizing on reliable protection equipment simplifies purchasing, reduces engineering time, and improves repeatability.

Development of standard BOMs integrating relays, power quality hardware, UPS, breakers, and enclosures.

Support for cutout, accessory, and panel layout consistency across multiple builds.

Reduced vendor complexity through a synergistic product portfolio,

Distributor Partnership & Local Support

ValuAdd works closely with regional electrical distributors to ensure product availability and fast support.

Joint customer calls, training sessions, and hands-on demonstrations.

Assistance with stocking strategies and demand planning.

Support for product launches, promotions, and field education,

ValuAdd brings together local presence, technical knowledge, strong distributor relationships, and a synergistic product portfolio, ensuring customers receive reliable solutions that reduce downtime, improve panel designs, and enhance operational performance.

Conclusion

Undervoltage is a silent but expensive threat to industrial operations. It causes intermittent failures, shortens equipment life, and disrupts production long before it is recognized as the root cause. The hidden cost is downtime, wasted troubleshooting effort, lost product quality, and unnecessary component replacement.

Preventing undervoltage requires a combination of:

Strong engineering and design fundamentals

The right protection and power quality equipment

Proper separation of critical control loads vs. power loads

Support from knowledgeable technical partners

With the right approach and the right tools, facilities can eliminate nuisance trips, protect equipment investment, and improve uptime performance.

Looking to improve system reliability, reduce nuisance trips, and protect your equipment from undervoltage? Connect with ValuAdd for application review, engineering support, and locally supported solutions.

Frequently Asked Questions (FAQ)

Q1: How do I know if undervoltage is happening in my facility if nothing is visibly failing?

Undervoltage often appears through subtle symptoms like intermittent drive trips, PLC resets, motor heating, or flickering lighting. The only reliable way to confirm is through logging and measurement at key points in the power path (service entrance, MCC, control panel).

Q2: Can undervoltage damage equipment even if breakers never trip?

Yes. Motors draw more current under undervoltage, causing overheating and shortened lifespan. Electronics can lock up or reset long before protection devices react.

Q3: Should every control panel include a UPS to prevent undervoltage problems?

Not necessarily. UPS should be reserved for automation and logic loads (PLCs, HMIs, IPCs, networking equipment). Motors and drives should use power quality conditioning and protection relays instead.

Q4: What’s the difference between a monitoring relay and a power quality solution?

Monitoring relays detect undervoltage and protect equipment by alarming or tripping. Power quality devices (reactors, filters) reduce voltage instability and distortion. They work best when used together.

Q5: Where should undervoltage protection be applied first?

Start with the most sensitive loads: control panels, PLC/IPC systems, VFD-heavy process lines, and mission-critical equipment. Then expand to plant-wide solutions.